How to calculate the diameter of pipes for heating. How to choose the right pipe diameter for heating a house? Calculation of heating a private house pipe diameter

It will not be difficult for any professional to determine the size of the required pipeline section. For this, there are special tables, according to which an experienced specialist will quickly find the right answer. Much harder for the average homeowner. He does not have professional knowledge, but the desire to independently create a heating circuit always exists. This article will help you correctly determine the diameter of the pipe for heating a private house.

The high efficiency of the heating system depends on a well-designed pipeline project. When planning pipe laying, it is very important to correctly calculate the possible heat losses. We must strive to minimize them as much as possible. If this is not done, then even huge energy costs will not help the heating system to function normally.

When buying pipes, you need to consider some properties of the material of the product:

- physical and chemical indicators;

- length;

- diameter.

Taking into account all these parameters will help to create a highly economical heating system with a high efficiency index.

What is the best pipe diameter to use for heating your private home? The hydrodynamic properties of the pipeline depend on the pipe section. It follows that the selection must be carried out carefully, observing all the required standards.

There is an opinion that if you increase the diameter of pipes for heating, the efficiency of the heating system will increase. However, this assertion is erroneous. When the diameter is unreasonably large, the pressure of the heating system decreases, it drops to the minimum values. As a result, the house remains without heating at all.

How to correctly choose the diameter of the pipes for installing the pipeline in your own cottage

The choice of pipe diameter for heating begins with determining how the coolant will be supplied. If it is carried out from the central highway, it is necessary to carry out the calculation in the same way as the supply of heat to a residential apartment.

If the cottage has an installed autonomous heating system, then the calculation of the diameter will depend on the type of pipe material and the existing heating scheme.

For example, if there is a natural circulation of water, it is necessary to install pipes with a certain diameter, and if an additional pump is connected, then this figure will be completely different.

What parameters you need to know in order to make the correct calculation of the diameter

The value of thermal power is considered very important. It depends on how efficiently the room will be heated. Usually this parameter is determined at the design stage of the boiler plant. If this is not done, then the approximate amount of heat is calculated depending on the volume of the room.

The cubic meter of the room will be normally heated by 40 watts. Therefore, to determine the heat consumption, you need to multiply the existing volume of the room by 40. The result should be in Watts.

Then the type of heating system is determined. He can be:

- single-pipe;

- two-pipe.

The second type of heating system in a private house is much better. It remains the most sought after and popular. One-pipe schemes have not been canceled. They are also used in heating systems.

The liquid moves in these systems according to the same laws, therefore, when determining the diameter of the pipeline, the type of heating is not decisive. Much more important mode of movement of the coolant. It can be of several types:

- convection, or gravity;

- forced: the movement is carried out with the help of a circulation pump.

These methods differ only in the movement of the coolant. With the convection method, the liquid moves through the pipeline very slowly. With forced - the pump makes it move much faster.

It is the rate of advancement of the coolant that is considered the most important parameter for calculating such a value as the diameter of the heating pipes. The throughput of the highway depends on its value. The recommended speed is in the range of 0.3 - 0.7 m/s.

When using the forced system, the speed is 0.7 m/s, for the convection method it is 0.3 m/s.

If the fluid velocity is less than the specified value, air bubbles will begin to form. If the pipeline diameter is very large, this will cause significant costs.

At high speed, the pipeline will start to make a lot of noise, the hydraulic resistance of the network will increase, and a conventional circulation pump may simply not be able to cope with such conditions.

Calculation of the pipe section

To understand the calculation methodology and get acquainted with the table of pipe diameters, let's take a typical calculation for the installation of a pipeline in a room with a total area of 20 sq. m:

After operations with the table, we got the following values: to normally heat a room of 20 square meters. m, it is necessary that the pipe has a diameter of 8 mm. The coolant will move at a speed of about 0.6 m/s. In this case, the consumption will be 105 kg / h, the value of the thermal power will not exceed 2453 W. It is allowed to use pipes with a cross section of 10 mm. Then the speed will reach 0.4 m/s. The consumption will be 110 kg/h. The power of the generated heat flux = 2555 W.

Now you know what pipe diameter to choose for heating.

If you choose the wrong diameter of the pipeline, a lot of problems may appear:

- leaks;

- high fuel consumption;

- high energy costs.

Therefore, the installation of such a heating system must be carried out taking into account all technological rules. For a circuit from a combination of dissimilar pipes, special calculations must be made. Separately, a plastic pipe is considered, separately metal. This task should only be performed by a specialist. It is not necessary to independently calculate the diameter, the error can reach a large value. The cost of the services of a professional is much less than the alteration of all communications during heating season. All devices must be connected only with pipes of the same cross section.

The construction of a heating system for a private house should begin with a thorough study of the project. The project must take into account all parameters that can affect the energy efficiency of the future heating system.

This includes the selection of a suitable boiler, batteries, layout, selection of pipe material and connecting elements. An equally important parameter is the correct calculation of the diameter of the pipelines.

It may seem to some that determining the required pipe diameter for a heating system is by no means a difficult task. It would seem that what requirements can be presented to the pipe, the only task of which is to deliver the coolant to the radiators.

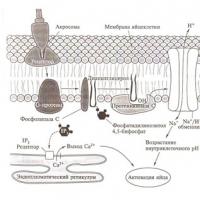

Meanwhile, an incorrectly selected diameter of the pipe (or collector) can adversely affect the operation of the entire heating system. The movement of fluid through a pipeline is accompanied by numerous complex processes, for the description of which there is a special branch of physics - hydrodynamics.

Without delving into the scientific jungle, it is possible, nevertheless, to determine a number of fundamental characteristics that directly depend on the diameter of the pipeline:

- The rate of spread of the liquid. It affects the optimal distribution of heat over the heating radiators, preventing the coolant from cooling below the minimum temperature value. In addition, the noise level of the operating heating system will directly depend on the propagation speed.

- Heat carrier volume. On the one hand, an increase in the diameter of the pipes will help reduce losses from fluid friction on the inner surface of the pipeline. On the other hand, with an increase in the cross section of the pipe, the total volume of the coolant in the system will increase, and more energy will be required to heat it.

- hydraulic losses. Occur at the joints of pipes of different diameters. The more transitions there are in the heating system, the more losses of this kind will result in the end.

Polypropylene pipe for heating.

One of the main points in the design of a heat supply system is the determination of the diameter of pipes for heating. The efficiency of the heating elements largely depends on the correct calculation. If the section of the mains is less than optimal, the house will be cool. Too large a diameter increases energy consumption, reducing the efficiency of using heating equipment.

Justification of the need for calculation

When drawing up a heat supply scheme, engineers set themselves two main tasks:

- avoid heat loss

- reduce energy consumption

Poorly designed heating circuits lead to excessive fuel consumption. At the same time, it is far from always possible to achieve a comfortable temperature in the house.

The choice of pipes depends not only on their physical and chemical parameters. The diameter of the lines also plays a very important role. It directly affects the hydrodynamics of the system, on which the level of heat supply depends. The prevailing opinion that a large pipe diameter is the most optimal is erroneous. Quite often, because of this, the pressure in the system drops, and the radiators simply cannot heat the room.

In private houses, the cross section is calculated based on the type of coolant supply. When connecting to centralized heat supply mains, the same principles are taken as the basis as when designing an apartment. For the organization of autonomous heat supply, the supply scheme and type of pipes are taken into account. There are differences in the forced and gravitational coolant circulation systems.

Pipe parameters

Before deciding which pipe diameter to choose for heating, you need to pay attention to the material of manufacture. After all, the markings of steel and cast iron pipes indicate the inner diameter, and those made of copper and plastic indicate the outer diameter. An insignificant nuance plays a very large role in the calculations.

The main characteristics of highways that are taken into account when planning:

- Internal section. This indicator is the basis for calculating the throughput of sections of the highway.

- Outside diameter. It is important for metal pipes. Their surface gives off heat to the room, thereby increasing the heat exchange area.

- Conditional diameter. This is the rounded value of the pipe diameter. Used for theoretical calculations and expressed in inches.

Reinforcing aluminum layer

Determining the cross section of the pipe for a particular room is not so difficult. It can be preliminarily calculated based on the thermal load. The indicator is static and generally accepted at the level of 100 watts per square meter. It follows from this that 2.4 kW of energy is needed to heat a room of 24 square meters. The supply of the required amount of coolant can be provided by a pipe with a diameter of ½ inch.

The results are selected from specially compiled tables:

Important! The thermotechnical calculation of a system with dissimilar pipes and radiators is very complicated. In this case, it is not worth solving the problem on your own. It is better to entrust the design to specialists.

When organizing autonomous heat supply, the owner of the house has the right to independently resolve issues related to the temperature of the coolant. There are no specific requirements in this regard. The temperature is determined depending on the thermal insulation of the building and external weather conditions. The diameter of the pipes for the heating system installed in the house is also important.

Pipe diameter for heating - questions of competent calculation

How to choose the right pipe diameter for heating? This question is always relevant in the design of autonomous systems. The efficiency and economy of the heat supply scheme depends on the internal section of the pipeline.

Pipe diameter for heating: how is this parameter selected?

When designing and building heating systems, it is extremely important not to make mistakes. Even at the stage of project development, the diameter of the heating pipes and their type should be determined.

The choice of these important parameters is carried out taking into account the expediency of their further operation.

Various diameters of heating pipes

Competent selection of pipe diameter - how important is it?

When designing heating circuits (for example, from polypropylene pipes), it is extremely important to try to avoid possible heat losses, that is, to reduce the required energy costs. Incorrectly planned systems (you can find out how to correctly develop a two-pipe heating system by reading the material on this topic) work inefficiently. As a result, despite the high energy consumption, the rooms will be cold and uncomfortable.

Pipes for mounting the system are chosen not only taking into account the physical and chemical properties of the material from which they are made. The length and diameter of the pipes play an important role in creating an economical and efficient system.

The fact is that the cross section of the pipes affects the hydrodynamics as a whole, therefore, how warm it will be in the house depends on the correct choice.

Ignorant people often make a common mistake when choosing pipes for heating - the diameter, they believe, should be as large as possible so that the water circulates freely.

In fact, an excessive increase in the cross section of the pipes will cause the pressure in the system to drop below normal, and the radiators will not heat up.

If you need to choose the diameter of the pipes for heating a private house, then, first of all, you should find out what type of coolant supply will be used. If the house is planned to be connected to a citywide heating main, then all calculations are carried out in exactly the same way as when equipping apartments.

When arranging autonomous heating systems, the size will depend on the chosen scheme and type of pipes. For example, the size of pipes for heating for a system with natural circulation of liquid will differ from a similar parameter when installed in a circulation pump circuit.

Main pipe parameters

Polypropylene heating pipes

- The main characteristic of any pipe is its inner diameter. It is from this indicator that the throughput of the pipe depends.

- The outside diameter is also an important parameter to consider when designing systems.

- It is customary to call the nominal diameter of the pipe a rounded value, expressed in inches.

When choosing pipe diameters for heating, it should be noted that different measurement systems are used for pipes made of different materials. For example, almost all pipes made of steel and cast iron are marked according to the internal section.

But pipes made of plastic and copper - according to the outer diameter. This feature should be taken into account if it is planned to assemble a system from a combination of materials.

When creating heating systems assembled from various materials, in order to accurately select pipes by diameter, you should use the diameter matching table, which can be downloaded on the network.

Connecting the pipe to the radiator

In order not to get confused in the calculations, it should be remembered that one inch is equal to 25.4 mm.

When solving the problem of what diameter of pipes for heating is needed in a given room, it is necessary to take into account such a parameter as heat load when calculating the diameter of pipes for heating. It is generally accepted that 100 W of thermal power per square meter of the room is enough to maintain comfortable conditions in the room (provided that the ceilings in the room are of standard height - 2.5 meters).

That is, for example, for heating a room with an area of 25 square meters, 2.5 kW of thermal energy is required (25 * 100 \u003d 2500 W \u003d 2.5 kW)

As can be seen from the data in the table, for our example with a room of 25 square meters, pipes with a diameter of 1/2 inch are suitable.

What should be the pressure and temperature of the coolant?

Example of mounted pipe and radiator

Having autonomous heating, the owner of the house himself chooses such a parameter as the temperature of the water in the heating pipes. It should be noted that there is no precisely established norm for this parameter, since it depends not only on external conditions and the desires of the owner, but also on the heat transfer coefficient of the installed heating radiators.

Cast iron radiators have the lowest heat transfer coefficient.

The average heat transfer rate for bimetallic models and the highest for aluminum radiators.

As a rule, the calculation of the number of radiators and their sections is carried out taking into account such a value as their passport thermal power. This parameter is set on the basis that the temperature of the heating water in the pipes will be equal to 75 degrees.

That is, if you think logically, then this temperature is optimal. However, when the external temperature changes in one direction or another, it is advisable to regulate the heating temperature of the coolant. This will help maintain a comfortable microclimate in the house and save energy.

Despite the fact that polypropylene pipes can withstand temperatures up to 110 degrees, it is not recommended that the temperature of the heating pipes exceed 95 degrees.

To increase the air temperature in the premises, it is more expedient to increase the working area of the radiators, and not to heat the coolant above the specified temperature.

Installation of heating pipes

In order for the heating system to function normally, the owner of the house must know what pressure should be in the heating pipes. For an autonomous system, the normal indicator is 1.5-2 atmospheres. If the pressure indicator reaches 3 atmospheres, then this is already a critical situation, threatening depressurization or equipment failure.

In order to be able to always check what pressure is in the heating pipes, pressure gauges must be included in the circuit. And in order to prevent excessive pressure, expansion tanks are used.

Thus, when designing and installing heating systems, there are no trifles. Any mistake can lead to a decrease in work efficiency. Therefore, it is desirable to entrust the creation of projects to professionals who are able to carry out hydraulic and thermal calculations.

The diameter of the pipe for heating a private house: how to calculate the optimal parameters of the heating system so that the water temperature and pressure are sufficient to heat the room, tips on choosing the communication material

56) Pipe diameter for heating a private house: how to calculate the optimal parameters of the heating system so that the water temperature and pressure are sufficient

We choose the diameter of pipes for heating: calculation scheme, characteristics depending on the material of manufacture

The correct design of the heating system is to take into account all possible factors influencing its efficiency. In addition to the correct selection of the main components, the boiler, radiators, safety groups, it is necessary to correctly calculate the section of the lines. To do this, you need to know the optimal diameter of the heating pipes: how to choose and calculate it yourself?

Difficulties in choosing the diameter of heating pipes

It would seem that choosing the diameter of pipes for heating a private house is not a difficult task. They should only ensure the delivery of the coolant from the source of its heating to the heat supply devices - radiators to batteries.

But in practice, an incorrectly selected diameter of the heating manifold or supply pipe can lead to a significant deterioration in the operation of the entire system. This is due to the processes that occur during the movement of water along the highways. To do this, you need to know the basics of physics and hydrodynamics. In order not to go into the jungle of precise calculations, you can determine the main characteristics of heating, which directly depend on the cross section of pipelines:

- Coolant movement speed. It affects not only the increase in noise during the operation of heat supply, but is also needed for optimal distribution of heat among heating devices. Simply, the water should not have time to cool to a minimum level when it reaches the last radiator in the system;

- Coolant volume. So, the diameter of pipes with natural circulation of heating should be large in order to reduce losses due to fluid friction on the inner surface of the line. However, along with this, the volume of the coolant increases, which entails an increase in the cost of heating it;

- Hydraulic losses. If different diameters are used in the system plastic pipes for heating, a pressure difference will inevitably arise at their junction, which will lead to an increase in hydraulic losses.

How to choose the diameter of the heating pipe so that, upon installation, you do not have to redo the entire heat supply system due to extremely low efficiency? First of all, you should perform the correct calculation of the section of the highways. To do this, it is recommended to use special programs and, if desired, check the result yourself manually.

At the junction, the diameters of polypropylene pipes for heating are reduced due to surfacing. The reduction in the cross section depends on the degree of heating during soldering and compliance with the installation technology.

The procedure for calculating the cross section of heat supply lines

Before calculating the diameter of a heating pipe, it is necessary to determine their basic geometric parameters. To do this, you need to know the main characteristics of highways. These include not only performance, but also dimensions.

Each manufacturer indicates the value of the pipe section - diameter. But in fact, it depends on the wall thickness and the material of manufacture. Before purchasing a specific model of pipelines, you need to know the following features of the designation of geometric dimensions:

- The calculation of the diameter of polypropylene pipes for heating is done taking into account the fact that manufacturers indicate the outer dimensions. To calculate the useful section, it is necessary to subtract two wall thicknesses;

- For steel and copper pipes, internal dimensions are given.

Knowing these features, you can calculate the diameter of the heating manifold, pipes and other components for installation.

When choosing polymer heating pipes, it is necessary to clarify the presence of a reinforcing layer in the design. Without it, when exposed hot water the highway will not have the proper rigidity.

Determination of the thermal power of the system

How to choose the right pipe diameter for heating and should it be done without calculated data? For a small heating system, complex calculations can be dispensed with. It is only important to know the following rules:

- The optimal diameter of pipes with natural circulation of heating should be from 30 to 40 mm;

- For a closed system with forced movement of the coolant, pipes of a smaller cross section should be used to create optimal pressure and water flow rate.

For an accurate calculation, it is recommended to use a program for calculating the diameter of heating pipes. If they are not, you can use approximate calculations. First you need to find the thermal power of the system. To do this, you need to use the following formula:

Where Q– calculated heat output of heating, kW/h, V- the volume of the room (house), m³, Δt- the difference between the temperatures in the street and in the room, ° С, To- the estimated heat loss coefficient of the house, 860 – value for converting the obtained values into an acceptable kWh format.

The greatest difficulty in the preliminary calculation of the diameter of plastic pipes for heating is caused by the correction factor K. It depends on the thermal insulation of the house. It is best taken from the table data.

As an example of calculating the diameters of polypropylene pipes for heating, you can calculate the required heat output of a room with a total volume of 47 m³. In this case, the temperature outside will be -23°С, and indoors - +20°С. Accordingly, the difference Δt will be 43°C. We take the correction factor equal to 1.1. Then the required thermal power will be.

The next step in choosing the diameter of the pipe for heating is to determine the optimal speed of the coolant.

The presented calculations do not take into account the correction for the roughness of the inner surface of the highways.

Water velocity in pipes

The optimal pressure of the coolant in the mains is necessary for the uniform distribution of thermal energy over radiators and batteries. For the correct selection of the diameters of the heating pipes, the optimal values \u200b\u200bof the speed of water advancement in pipelines should be taken.

It is worth remembering that if the intensity of movement of the coolant in the system is exceeded, extraneous noise may occur. Therefore, this value should be between 0.36 and 0.7 m/s. If the parameter is less, additional heat losses will inevitably occur. If it is exceeded, noise will appear in pipelines and radiators.

For the final calculation of the diameter of the heating pipe, use the data from the table below.

Substituting into the formula for calculating the diameter of the heating pipe in the previously obtained values, it can be determined that the optimal pipe diameter for a particular room will be 12 mm. This is just an approximate calculation. In practice, experts recommend adding 10-15% to the obtained values. This is because the formula for calculating the diameter of the heating pipe may change due to the addition of new components to the system.

For an accurate calculation, you will need a special program for calculating the diameter of heating pipes. Similar software systems can be downloaded in a demo version with limited calculation capabilities.

Calculation of the heating manifold and mounting sleeves

The above calculation technology can be applied to all types of heat supply - one-pipe, two-pipe and collector. However, for the latter, it is necessary to make a correct calculation of the diameter of the heating collector.

This heating element is necessary for the distribution of the coolant over several circuits. In this case, the calculation of the correct diameter of the heating manifold is inextricably linked with the calculation of the optimal section of the pipeline. This is the next stage in the design of the heating system.

To calculate the diameter of the heating manifold, you must first calculate the cross section of the pipes according to the above scheme. Then you can use a fairly simple formula:

When determining the height and the optimal distance between the nozzles, the principle of "three diameters" is applied. According to him, the remoteness of the pipes on the structure should be 6 radii each. The total diameter of the heating manifold is also equal to this value.

But in addition to this component of the system, it is often necessary to use additional ones. How to find out the diameter of the sleeve for heating pipes? Only by performing a preliminary calculation of the section of highways. In addition, you need to take into account the thickness of the walls and the material of their manufacture. The design of the sleeve, the degree of its thermal insulation will depend on this.

The diameter of the sleeve for heating pipes is influenced by the material of the wall, as well as the pipes. It is important to take into account the possible degree of expansion when the surface is heated. If the diameters of the plastic heat supply pipes are 20 mm, then the same parameter for the sleeve must be at least 24 mm.

The sleeve must be mounted on cement mortar or similar non-combustible material.

Additional data for calculating the diameter of heat supply pipes

After choosing the diameter of the pipes for heating a private house, you need to choose the right material for their manufacture, as well as take into account the features of the heating system. This parameter is affected by the layout of the highways, as well as the number of shut-off and control valves.

In addition to knowing the diameter of pipes in heating with natural circulation, it is necessary to take into account the height of the accelerating riser and choose the right size for its cross section. It must be at a minimum height of 1.5 in relation to other heating elements. To increase the speed of the coolant, the diameter of the polypropylene pipes used in the design of the accelerating manifold must be one size larger than that of the main line.

It is also important to consider the wall thickness of the pipelines. It depends on the material of manufacture and can vary from 0.5 mm (steel) to 5 mm (plastic). The choice of pipe diameter for the heating system of a private house is influenced by the material of manufacture. So, plastic lines are recommended to be installed for systems with forced circulation. Their inner diameter can vary from 10 to 30 mm. You can learn more about the wall thickness of polymer pipes for heating from the data in the table.

For steel models, it is necessary to take into account not only their geometric dimensions, but also their weight. It directly depends on the wall thickness. In programs for calculating the diameter of heating pipes, there must be a function for calculating the specific gravity of 1 m.p. steel line.

Knowing these additional characteristics, it is possible to make the most accurate calculation of the parameters of the heating system, including the correct selection of the diameters of the heating pipes.

Heating pipe material

Apart from right choice pipe diameters for heat supply, you need to know the characteristics of their material of manufacture. This will affect the heat loss of the system, as well as the complexity of installation.

It should be remembered that the calculation of the diameters of heating pipes is performed only after choosing the material for their manufacture. Currently, several types of pipelines are used to complete heat supply systems:

- Polymer. They are made of polypropylene or cross-linked polyethylene. The difference lies in the additional components added during the production process. After calculating the diameter of polypropylene pipes for heat supply, you need to choose the right thickness of their wall. It varies from 1.8 to 3 mm, depending on the parameters of the maximum pressure in the lines;

- Steel. Until recently, this was the most common option for arranging heating. Despite their more than good strength characteristics, steel pipes have a number of significant drawbacks - complex installation, gradual surface rusting and increased roughness. Alternatively, pipes made of stainless steel can be used. One of their cost is an order of magnitude higher than the "black" ones;

- Copper. For technical and performance characteristics copper piping is the best option. They are characterized by sufficient stretching, i.e. if water freezes in them, the pipe will expand for some time without loss of tightness. The disadvantage is the high cost.

In addition to the correctly selected and calculated diameter of the pipes, it is necessary to determine the method of their connection. It also depends on the material of manufacture. For polymers, a coupling connection is used by welding or on an adhesive basis (very rarely). Steel pipelines are mounted using arc welding (better quality connections) or threaded method.

Diameter of heating pipes: how to choose and calculate correctly

We choose the diameter of the pipes for heating: difficulties in choosing, the procedure for calculating the cross section according to the power of the system and the speed of the water, additional calculation of the collector and sleeves.

Menu:

Designing and is a difficult task. When solving it, it is important to take into account all the existing nuances. First of all, you need to decide on the diameter of private houses or apartments. This is important for both one-pipe and two-pipe systems.

Selection of pipe diameter, what will happen if you do not choose the right one?

When designing a heating circuit, it is necessary to minimize possible heat losses in order to reduce energy costs. An incorrectly designed system works inefficiently. The temperature in the room will not increase, and energy costs will be excessive.

When take into account not only the chemical properties of the materials for the manufacture of channels, but also the indicator of their diameter. This indicator plays an important role. It depends on how efficiently the system will work. The cross section of the channels strongly affects the hydrodynamics. His choice should be given enough attention.

There is an opinion that the larger the cross section of the channels, the better the carrier circulates in them. However, this is absolutely not the case. Excessive diameter of pipes connected to gas or electric boilers, leads to a decrease in pressure in the system. As a result, the radiators do not receive enough heat.

If you need to equip a heating circuit in a private house, you need to decide on the type of media supply. If the building is connected to a municipal heating main, the design and installation process will be similar to the arrangement of the system in an apartment.

Autonomous heating system can have different schemes. The choice of the channel cross-section indicator directly depends on them. Dimensions of structures for systems with a natural type of carrier circulation differ from options based on the use of pumps.

Main characteristics of pipes

All existing channels have several section parameters. You need to understand this. Otherwise, you can make a mistake, and get exactly the designs that you need.

The following structural section options are available:

- internal;

- external;

- conditional.

The key parameter is the inner diameter of the channel. On its basis, the design capacity index is calculated. The outer section is also taken into account when planning the contour. It is very important when installing the system. A conditional section is a rounded diameter indicator. As a rule, it is indicated in inches.

When choosing channels for creating a heating circuit, you need to understand that products made from different materials using different measurement systems. For example, structures are marked exclusively in terms of the internal section, and and - in terms of the outer diameter.

In addition, plastic channels are of various types.

To date, the following types of polymer pipes are produced:

Plastic structures may have various technical specifications. The most convenient for creating a heating system are pipes made of reinforced polypropylene. But metal-plastic and polyethylene structures are also used to solve this problem. Before making a choice in favor of one or another product, study its features in detail. This is the only way to choose the most best option.

Below, see the table of correspondence of pipe diameters made of different materials. She will help you make the right choice.

Correspondence table of outer diameters and conditional passages of steel and polymer pipes

Most often, the cross section is indicated in inches. This applies to all kinds of channels. Don't forget that one inch is 25.4mm.

How to calculate?

To carry out correct calculations, the magnitude of the heat load must be taken into account. It is believed that one hundred watts per square meter is enough to create a normal temperature in the room. This is true for rooms with a ceiling height of two and a half meters.

Thus, 2.5 kW of thermal energy is needed to heat rooms of twenty-five square meters. Channel selection can be done using the table below.

Based on the tabular data, half-inch structures should be used to heat rooms of twenty-five square meters.

Pressure and temperature in the heating system

When creating autonomous systems, you yourself determine the required temperature of the carrier in the circuit. There is no approved standard. This figure depends not only on environmental conditions and your own preferences, but also on the value of the heat transfer coefficient of the batteries. This parameter is the lowest in . Bimetallic products are characterized by an average value of the coefficient. The highest parameter for batteries made of aluminum.

In principle, the indicated temperature regime is optimal. But if the conditions of the external environment change, it must be changed up or down. Depending on the circumstances. Adjusting the temperature will allow you to create more comfortable conditions in the room, and reduce energy costs.

If you choose polypropylene channels to create a heating circuit, please note that the temperature regime inside them should not exceed ninety-five degrees.

To make the system more efficient, it is better to increase the number of batteries or sections in them than to raise the temperature of the carrier above the specified mark.

To ensure the normal functioning of the circuit, monitor the pressure indicator. For autonomous systems, its value should be from 1.5 to 2 atmospheres. If the pressure rises higher, it can lead to an emergency. As a result, channels and other equipment will fail.

To control the pressure indicator, you need to use a manometer. Expansion tanks will allow you to avoid the occurrence of unacceptable pressure in the system.

Installation and wiring of the system - installation

For the construction of a heating circuit in a private house, you need to take into account some details. There are different system wiring diagrams. It is important to choose and design the most optimal option. Carrier circulation can be natural or forced. In some cases, the first option is convenient, in others - the second.

Natural circulation occurs by changing the density of the fluid. Hot media is characterized by a lower density index. The water on the way back is denser. Thus, the heated liquid rises along the riser and moves along horizontal lines. They are mounted at a slight angle of no more than five degrees. The slope allows the media to move by gravity.

The heating scheme, which works on the basis of natural circulation, is considered the simplest. To perform its installation, you do not need to be highly qualified. But it is only suitable for small buildings. The length of the line in this case should not exceed thirty meters. Of the minuses of this scheme, one can single out low pressure inside the system and the need to use channels of a significant cross section.

Forced circulation implies the presence of a special circulation pump. Its function is to ensure the movement of the carrier along the highway. When implementing a scheme with forced fluid movement, it is not necessary to create a contour slope. Of its shortcomings, one can single out the energy dependence of the system. If a power outage occurs, media movement in the system will be hindered. Therefore, it is desirable that the house has its own generator.

The wiring happens:

- Single pipe.

- Two-pipe.

The first option is implemented through the sequential flow of the carrier through all radiators. This scheme is economical. For its implementation, a minimum number of pipes and fittings for them is required.

The one-pipe scheme has a number of disadvantages. You will not be able to adjust the media advance for each battery. As you move away from the boiler, the radiators will be less warm. It is possible to overcome these defects.

To do this, you need to use the so-called "Leningrad" wiring diagram.

It involves the installation of bypass pipes and valves on each radiator. This principle makes it possible to ensure uninterrupted circulation of the carrier when any battery is cut off.

Installing a two-pipe heating scheme in a private house consists in connecting reverse and direct current to each radiator. This increases the channel consumption by about two times. But the implementation of this option allows you to adjust the heat transfer in each battery. Thus, it will be possible to adjust the temperature regime in each individual room.

Two-pipe wiring is of several types:

- lower vertical;

- top vertical;

- horizontal.

The lower vertical wiring means starting the supply circuit along the floor of the lower floor of the building or its basement. Then, from the main line, the carrier goes up through the risers and enters the radiators. From each device there is a "return", delivering the cooled liquid to the boiler. Implementing this scheme, you need to install an expansion tank. There is also a need to install Mayevsky cranes on all heating devices located on the upper floors.

The top vertical wiring is arranged differently. From the heating unit, the liquid goes to the attic. Next, the carrier moves down through several risers. It goes through all the radiators and returns to the unit along the main circuit. An expansion tank is needed to remove air from this system. This scheme is more efficient than the previous one. Since there is a higher pressure inside the system.

The horizontal two-pipe type with forced circulation is the most popular.

It comes in three varieties:

- with radial distribution (1);

- with associated movement of fluid (2);

- dead end (3).

The variant with beam distribution consists in connecting each battery to the boiler. This principle of operation is the most convenient. Heat is evenly distributed in all rooms.

The option with associated fluid movement is quite convenient. All lines leading to the radiators are of equal length. Adjustment of such a system is quite simple and convenient. To install this wiring, you need to purchase a significant number of channels.

The latter option is implemented by using a small number of channels. Minus - a significant length of the circuit from the distant battery, which complicates the adjustment of the functioning of the system.

How to hide pipes

When building heating circuits, many owners think about how to hide heating pipes in a private house. This problem can be solved in different ways.

Most often, for covert installation of channels, they resort to:

- the use of decorated structures;

- closing channels under drywall;

- hiding products under suspended ceiling panels;

- installation under a raised floor;

- hiding structures in the walls of the building.

The choice of method depends on many factors. It is advisable to consult with experts to solve this problem. Many details must be taken into account. Including the materials from which the building is made. It can be brick, aerated concrete, etc.

conclusions

When designing and installing heating systems, every detail must be taken into account. In this case, there are no trifles that you can turn a blind eye to. Mistakes made at the planning stage will lead to serious consequences. As a result, you will have to redevelop the circuit, dismantle the old system, and install a new one. The design phase must be carried out by a competent and experienced person.

With two-pipe wiring, the most important thing is not to make a mistake with the choice of pipe diameter. Otherwise, heating will not be uniform, or even absent on some heaters. This material is based solely on my own experience. If you stick to it, then everything will work.

First, let's define the basic terms:

- supply pipe - a pipe of any diameter through which the heated coolant enters the radiators, warm floor, convectors, etc., (See also: Two-pipe heating system of a private house)

- return pipe - a pipe of any diameter through which the coolant returns to the boiler; in a correct two-pipe system, the diameters of the supply and return pipes are equal at the same points.

- shoulder - pipe outlet through the tee in an additional direction, shoulders can also be at an existing shoulder. There are always two of them, according to the number of branches at the tee. For most domestic boilers, the diameter of the supply and return pipes is 1 inch (d25) or an inch and a quarter (d32). There are boilers in which the diameter of the outlets is three quarters (d20). With such boilers, it is better to build a single-pipe circuit. Let's look at the ruler of diameters. It looks like this: d32, d25, d20, d16. The main rule for forming the pipe diameter: after each tee, the diameter decreases by one position when passing from the boiler to the last radiator. For example: you have a d32 pipe coming from the boiler. On the first radiator you have d16. Next comes d25. D16 goes to the second radiator. Next comes d20. D16 goes to the third radiator. And the last one is d16. We see that 4 radiators are “hanging” on the pipe. (See also: Contemporary water heating) And what if there are more radiators? Very simple. We spread the pipe on two shoulders. d32 comes out of the cauldron. Through the tee we dissolve two pipes, but already d25. From each d25 we assign d16 to the radiators, then d20 goes. From each d20 we assign d16 to two more radiators, then d16 goes to two more radiators. As you can see, we already have six radiators. Also, I can say with absolute certainty that if you make a diversion of d16 from d16 to two radiators and throw further d16 to two more radiators, then such a system will work. Therefore, we already have eight radiators.

The considered system will work without balancing. If there are any deviations from this principle, then you will need to balance the radiators, that is, with the help of valves, limit the flow to the hottest ones so that the heat reaches the less heated ones. The more heatsinks you have, the less efficient the system is. Eight is the best option.

Selection of pipe diameter in a two-pipe heating system

When distributing a two-pipe heating system, it is very important to choose the correct pipe diameter. Otherwise, heating will not be uniform, or even absent on some heaters.

How to choose the diameter of pipes for heating

In the article we will consider systems with forced circulation. In them, the movement of the coolant is provided by a constantly operating circulation pump. When choosing the diameter of pipes for heating, they proceed from the fact that their main task is to ensure the delivery of the required amount of heat to heating devices - radiators or registers. For the calculation, the following data will be needed:

- General heat loss of a house or apartment.

- The power of heating devices (radiators) in each room.

- Pipeline length.

- Method of distributing the system (single-pipe, two-pipe, with forced or natural circulation).

That is, before proceeding with the calculation of pipe diameters, you first calculate the total heat loss, determine the boiler power and calculate the radiator power for each room. It will also be necessary to decide on the method of wiring. Based on these data, draw up a diagram and then only proceed to the calculation.

To determine the diameter of pipes for heating, you will need a diagram with spaced values of the heat load on each element

What else you need to pay attention to. For the fact that the outer diameter is marked for polypropylene and copper pipes, and the inner diameter is calculated (subtract the wall thickness). For steel and metal-plastic, when marking, the internal size is affixed. So don't forget this little thing.

How to choose the diameter of the heating pipe

Let's explain. It is important for us to deliver the right amount of heat to the radiators and at the same time achieve uniform heating of the radiators. In systems with forced circulation, we do this with pipes, a coolant and a pump. In principle, all we need is to "drive" a certain amount of coolant over a certain period of time. There are two options: to install pipes of smaller diameter and supply the coolant at a higher speed, or to make a system with a larger cross section, but with less traffic. Usually the first option is chosen. And that's why:

- the cost of products of smaller diameter is lower;

- they are easier to work with;

- when laid open, they do not attract attention so much, and when laying in the floor or walls, smaller strobes are required;

- with a small diameter, there is less coolant in the system, which reduces its inertia and leads to fuel economy.

Calculation of the diameter of copper heating pipes depending on the power of the radiators

Since there is a certain set of diameters and a certain amount of heat that needs to be delivered through them, it is unreasonable to count the same thing every time. Therefore, special tables were developed, according to which, depending on the required amount of heat, the speed of the coolant and the temperature indicators of the system, the possible size is determined. That is, to determine the cross section of pipes in the heating system, find the desired table and select the appropriate cross section for it.

The calculation of the diameter of pipes for heating was carried out according to this formula (if you wish, you can calculate it). Then the calculated values were recorded in a table.

The formula for calculating the diameter of the heating pipe

D - desired pipeline diameter, mm

∆t° - temperature delta (difference between supply and return), °С

Q - load on a given section of the system, kW - the amount of heat determined by us, required for space heating

V - coolant velocity, m/s - is selected from a certain range.

In systems individual heating the speed of movement of the coolant can be from 0.2 m/s to 1.5 m/s. Based on operating experience, it is known that the optimal speed is in the range of 0.3 m/s - 0.7 m/s. If the coolant moves more slowly, air locks occur, if faster, the noise level increases greatly. The optimal speed range is selected in the table. Tables are designed for different types pipes: metal, polypropylene, metal-plastic, copper. Values are calculated for standard operating modes: with high and medium temperatures. To make the selection process more understandable, we will analyze specific examples.

Calculation for a two-pipe system

There is a two-storey house with a two-pipe heating system, two wings on each floor. Polypropylene products will be used, operating mode 80/60 with a temperature delta of 20 ° C. The heat loss of the house is 38 kW of thermal energy. The first floor has 20 kW, the second 18 kW. The diagram is shown below.

Two-pipe heating scheme two-story house. Right wing (click to enlarge)

Two-pipe heating scheme for a two-story house. Left wing (click to enlarge)

On the right is a table by which we will determine the diameter. The pinkish area is the zone of optimal coolant velocity.

Table for calculating the diameter of polypropylene heating pipes. Operating mode 80/60 with a temperature delta of 20°C (click to enlarge)

- We determine which pipe should be used in the area from the boiler to the first branch. The entire coolant passes through this section, therefore the entire volume of heat of 38 kW passes. In the table we find the corresponding line, along it we reach the zone tinted with pink and go up. We see that two diameters are suitable: 40 mm, 50 mm. For obvious reasons, we choose the smaller one - 40 mm.

- Let's look at the diagram again. Where the flow is divided, 20 kW goes to the 1st floor, 18 kW goes to the 2nd floor. In the table we find the corresponding lines, determine the cross section of the pipes. It turns out that both branches are bred with a diameter of 32 mm.

- Each of the circuits is divided into two branches with equal load. On the first floor, 10 kW go to the right and left (20 kW/2=10 kW), on the second floor, 9 kW (18 kW/2)=9 kW). According to the table we find the corresponding values for these sections: 25 mm. This size is used further until the heat load drops to 5 kW (see the table). Next comes a section of 20 mm. On the first floor, we pass 20 mm after the second radiator (look at the load), on the second - after the third. At this point, there is one amendment made by accumulated experience - it is better to switch to 20 mm at a load of 3 kW.

All. The diameters of polypropylene pipes for a two-pipe system are calculated. For the return, the cross section is not calculated, and the wiring is made by the same pipes as the supply. The methodology is hopefully clear. It will not be difficult to carry out a similar calculation in the presence of all the initial data. If you decide to use other pipes, you will need other tables calculated for the material you need. You can practice on this system, but already for an average temperature regime of 75/60 and a delta of 15 ° C (the table is located below).

Table for calculating the diameter of polypropylene heating pipes. Operating mode 75/60 and delta 15 °C (click to enlarge)

Determining the pipe diameter for a one-pipe system with forced circulation

The principle remains the same, the methodology changes. Let's use another table to determine the diameter of pipes with a different principle for entering data. In it, the optimal zone of coolant flow rates is colored blue, the power values are not in the column on the side, but are entered in the field. Because the process itself is a little different.

Table for calculating the diameter of heating pipes

Based on this table, we calculate interior pipe diameter for a simple single-pipe heating scheme for one floor and six radiators connected in series. Let's start the calculation:

- 15 kW is supplied to the system input from the boiler. We find in the zone of optimal speeds (blue) values close to 15 kW. There are two of them: in a line with a size of 25 mm and 20 mm. For obvious reasons, we choose 20 mm.

- On the first radiator, the heat load is reduced to 12 kW. Find this value in the table. It turns out that it goes further of the same size - 20 mm.

- On the third radiator, the load is already 10.5 kW. We determine the cross section - all the same 20 mm.

- The fourth radiator, judging by the table, is already 15 mm: 10.5 kW-2 kW = 8.5 kW.

- On the fifth goes another 15mm, and after it you can already put 12mm.

Scheme of a single-pipe system for six radiators

Again, note that the table above defines internal diameters. On them, you can then find the marking of pipes from the desired material.

It seems that there should be no problems with how to calculate the diameter of the heating pipe. Everything is clear enough. But this is true for polypropylene and metal-plastic products - their thermal conductivity is low and losses through the walls are insignificant, therefore, they are not taken into account in the calculation. Another thing - metals - steel, stainless steel and aluminum. If the length of the pipeline is significant, then the losses through their surface will be significant.

Features of calculating the cross section of metal pipes

For large heating systems with metal pipes, heat loss through the walls must be taken into account. The losses are not so great, but with a large length they can lead to the fact that the temperature on the last radiators will be very low due to the wrong choice of diameter.

Calculate the losses for a steel pipe 40 mm with a wall thickness of 1.4 mm. Losses are calculated by the formula:

q - heat loss of a pipe meter,

k - linear heat transfer coefficient (for a given pipe it is 0.272 W * m / s);

tv - water temperature in the pipe - 80°С;

tp - air temperature in the room - 22°C.

Substituting the values we get:

It turns out that almost 50 watts of heat is lost per meter. If the length is significant, this can become critical. It is clear that the larger the cross section, the greater the losses. If it is necessary to take into account these losses, then when calculating the losses, the losses in the pipeline are added to the reduction of the heat load on the radiator, and then, from the total value, the required diameter is found.

Determining the diameter of pipes in a heating system is not an easy task.

But for individual heating systems, these values \u200b\u200bare usually not critical. Moreover, when calculating the heat loss and power of the equipment, most often the calculated values are rounded upwards. This gives a certain margin, which allows you not to do such complex calculations.

An important question: where to get the tables? Almost all manufacturers' websites have such tables. You can read directly from the site, or you can download it for yourself. But what to do if you still did not find the necessary tables for the calculation. You can use the diameter selection system described below, or you can do it differently.

Despite the fact that when marking different pipes, different values \u200b\u200bare indicated (internal or external), they can be equated with a certain error. From the table below, you can find the type and marking with a known inside diameter. Here it will be possible to find the corresponding size of the pipe from another material. For example, you need to calculate the diameter of metal-plastic heating pipes. You did not find a table for MP. But there is for polypropylene. You select the dimensions for the PPR, and then, using this table, find analogues in the MP. Naturally, there will be an error, but for systems with forced circulation it is permissible.

Correspondence table for different types of pipes (click to enlarge)

Using this table, you can easily determine the inner diameters of the pipes of the heating system and their marking.

Selection of pipe diameter for heating

This method is not based on calculations, but on a pattern that can be traced when analyzing a fairly large number of heating systems. This rule was developed by installers and is used by them on small systems for private houses and apartments.

The diameter of the pipes can simply be selected following a certain rule (click to enlarge)

Most heating boilers have two sizes of supply and return pipes: ¾ and ½ inches. It is with such a pipe that the wiring is made to the first branch, and then on each branch the size is reduced by one step. In this way, you can determine the diameter of the heating pipes in the apartment. Systems are usually small - from three to eight radiators in the system, a maximum of two or three branches with one or two radiators on each. For such a system, the proposed method is an excellent choice. The situation is practically the same for small private houses. But if there are already two floors and a more branched system, then you have to count and work with tables.

With a not very complex and branched system, the diameter of the pipes of the heating system can be calculated independently. To do this, you need to have data on the heat loss of the room and the power of each radiator. Then, using the table, you can determine the section of the pipe that will cope with the supply of the required amount of heat. It is better to entrust the cutting of complex multi-element circuits to a professional. As a last resort, calculate on your own, but try, at a minimum, to get advice.

The diameter of the pipes of the heating system: calculation, formula, selection

What pipe diameter should I choose? How to calculate or choose it? Methods and tables for determining pipe diameters. Diameter calculation example for

All about two-pipe heating systems

A two-pipe heating system is more complex than a single-pipe one, and the amount of materials needed for installation is much larger. Nevertheless, it is the 2-pipe heating system that is more popular. As the name suggests, it uses two circuits. One serves to deliver the hot coolant to the radiators, and the second takes the cooled coolant back. Such a device is applicable for any type of structures, as long as their layout allows the installation of this structure.

A two-pipe heating system is more complex than a single-pipe one, and the amount of materials needed for installation is much larger. Nevertheless, it is the 2-pipe heating system that is more popular. As the name suggests, it uses two circuits. One serves to deliver the hot coolant to the radiators, and the second takes the cooled coolant back. Such a device is applicable for any type of structures, as long as their layout allows the installation of this structure.

Advantages and disadvantages

The demand for a double-circuit heating system is due to the presence a number of significant benefits . First of all, it is preferable to a single-circuit one, since in the latter the coolant loses a significant part of the heat even on the way to the radiators. In addition, the double-circuit design is more versatile and is suitable for houses of different heights.

The disadvantage of a two-pipe system its higher value is considered. However, many people mistakenly believe that since the presence of 2 circuits implies the use of twice the number of pipes, then the cost of such a system is twice that of a single-pipe system. The fact is that for a single-pipe design it is necessary to take pipes of large diameter. This ensures the normal circulation of the coolant in the pipeline, and hence the efficient operation of such a design. The advantage of a two-pipe is that for its installation, pipes of a smaller diameter are taken, which are much cheaper. Accordingly, additional elements for installation (drives, valves, etc.) are also used with a smaller diameter, which also somewhat reduces the cost of the system.

Thus, the budget for installing a two-pipe system will not be much larger than for a single-pipe system. On the other hand, the efficiency of the former will be noticeably higher, which will be a good compensation for the increased costs.

Application example

One of the places where two-pipe heating will be very useful is garage. This is a working room, so there is no need for constant heating. In addition, a do-it-yourself two-pipe heating system is a very real undertaking. Heating in the garage is not necessary, but it will be absolutely not superfluous, since it is very difficult to work here in winter: it is not easy to start the engine, the oil freezes, and it is very uncomfortable to just work with your hands. The two-pipe heating system provides quite acceptable conditions for working indoors.

Varieties of two-pipe systems for heating

There are several criteria by which such heating structures can be classified.

open and closed

Closed systems suggest the use of an expansion tank with a membrane. They can work with high blood pressure. Instead of ordinary water in closed systems, heat transfer fluids based on ethylene glycol, which do not freeze at low temperatures (up to 40 °C below zero). Motorists know such fluids called "antifreeze".

1. Heating boiler; 2. Security group; 3. Overpressure relief valve; 4. Radiator; 5. Return pipe; 6. Expansion tank; 7. Valve; 8. Drain valve; 9. Circulation pump; 10. Pressure gauge; 11. Make-up valve.

1. Heating boiler; 2. Security group; 3. Overpressure relief valve; 4. Radiator; 5. Return pipe; 6. Expansion tank; 7. Valve; 8. Drain valve; 9. Circulation pump; 10. Pressure gauge; 11. Make-up valve.

However, we must remember that for heating devices there are special compositions of coolants, as well as special additives and additives. The use of conventional substances can lead to the breakdown of expensive heating boilers. Such cases can be regarded as non-warranty, because the repair will require significant costs.

open system characterized by the fact that expansion tank must be installed strictly at the highest point of the device. It must be provided with a pipe for air and a drain pipe through which excess water is drained from the system. Also through it you can take warm water for household needs. However, such use of the tank requires automatic feeding of the structure and excludes the possibility of using additives and additives.

1. Heating boiler; 2. Circulation pump; 3. Heating appliances; 4. Differential valve; 5. Gate valves; 6. Expansion tank.

1. Heating boiler; 2. Circulation pump; 3. Heating appliances; 4. Differential valve; 5. Gate valves; 6. Expansion tank.

And yet, a closed-type two-pipe heating system is considered safer, so modern boilers are most often designed for it.

Horizontal and vertical

These types differ in the location of the main pipeline. It serves to connect all elements of the system. Both horizontal and vertical systems have their own advantages and disadvantages. However, both designs exhibit good heat dissipation and hydraulic stability.

Two-pipe horizontal heating design found in single storey buildings. vertical also used in high-rise buildings. It is more complex and therefore more expensive. Here, vertical risers are used, to which heating elements are connected on each floor. The advantage of vertical systems is that they usually do not have air locks, since the air exits through the pipes up to the expansion tank.

Systems with forced and natural circulation

Such types differ in that, firstly, there is an electric pump that causes the coolant to move, and secondly, the circulation occurs on its own, obeying physical laws. The disadvantage of designs with a pump is that they depend on the availability of electricity. For small rooms, there is no particular point in forced systems, except that the house will heat up faster. With large areas, such structures will be justified.

In order to choose the right type of circulation, it is necessary to consider which piping type used: upper or lower.

Top wiring system

involves laying the main pipeline under the ceiling of the building. This provides a high pressure of the coolant, so that it passes well through the radiators, which means that the use of a pump will be redundant. Such devices look more aesthetic, the pipes at the top can be hidden decorative elements. However, a membrane tank must be installed in a top-wired system, which entails additional costs. It is also possible to install an open tank, but it must be at the highest point of the system, that is, in the attic. In this case, the tank must be insulated.

Bottom wiring

involves the installation of a pipeline just below the windowsill. In this case, you can install an open expansion tank anywhere in the room slightly above the pipes and radiators. But without a pump in such a design is indispensable. In addition, difficulties arise if the pipe must pass by the doorway. Then it is necessary to let it run along the perimeter of the door or make 2 separate wings in the contour of the structure.

Dead end and passing

In a dead end system hot coolant and cooled coolant go to different directions. In a passing system constructed according to the Tichelman scheme (loop), both flows go in the same direction. The difference between these types is the ease of balancing. If the associated system, when using radiators with an equal number of sections, is already balanced in itself, then in a dead-end system, a thermostatic valve or a needle valve must be installed on each radiator.

If, in the Tichelman scheme, radiators with an unequal number of sections are used, the installation of valves or valves is also required here. But even in this case, such a design is balanced easier. This is especially noticeable in extended heating systems.

Selection of pipes by diameter

The choice of pipe section must be made based on the volume of coolant that must pass per unit of time. It, in turn, depends on the heat output required to heat the room.

In our calculations, we will proceed from the fact that the amount of heat loss is known and there is a numerical value of the heat required for heating.

Calculations begin with the final, that is, the farthest radiator of the system. To calculate the coolant flow rate for a room, you need the formula:

- G - water consumption for space heating (kg / h);

- Q is the thermal power required for heating (kW);

- c is the heat capacity of water (4.187 kJ/kg×°C);

- Δt is the temperature difference between the hot and cooled coolant, assumed to be 20 °C.

For example, it is known that the heat output for space heating is 3 kW. Then the water consumption will be:

3600×3/(4.187×20)=129 kg/h, i.e. about 0.127 cu. m of water per hour.

In order for water heating to be balanced as accurately as possible, it is necessary to determine the cross section of the pipes. For this we use the formula:

- S is the cross-sectional area of the pipe (m2);

- GV is the volume flow of water (m3/h);

- v is the speed of water movement, is in the range of 0.3−0.7 m/s.

If the system uses natural circulation, then the speed of movement will be minimal - 0.3 m / s. But in this example, let's take the average value - 0.5 m / s. According to the indicated formula, we calculate the cross-sectional area, and based on it, the inner diameter of the pipe. It will be 0.1 m. We select polypropylene pipe nearest larger diameter. This is a pipe with an inner diameter of 15 mm. We will use it in our design.

Then we move on to the next room, calculate the coolant flow rate for it, sum it up with the flow rate for the calculated room and determine the pipe diameter. And so to the boiler.

System installation

When installing the structure, certain rules should be followed:

- any two-pipe design includes 2 circuits: the upper one serves to supply hot coolant to the radiators, the lower one - to drain the cooled coolant;

- the pipeline should have a slight slope towards the final radiator;

- the pipes of both circuits must be parallel;

- the central riser must be insulated to prevent heat loss when the coolant is supplied;

- in reversible two-pipe systems, it is necessary to provide several taps with which it is possible to drain water from the device. This may be needed during repair work;

- when designing a pipeline, it is necessary to provide for the smallest possible number of angles;

- the expansion tank must be installed at the highest point in the system;

- diameters of pipes, taps, spurs, connections must match;

- when installing a pipeline from heavy steel pipes, special fasteners must be installed to support them. The maximum distance between them is 1.2 m.

How to make the correct connection of heating radiators, which will ensure the most comfortable conditions in the apartment? When installing two-pipe heating systems, it is necessary to adhere to the following sequence:

- The central riser of the heating system is diverted from the heating boiler.

- At the highest point, the central riser ends with an expansion tank.

- Pipes run from the tank throughout the building, which bring the hot coolant to the radiators.

- To remove the cooled coolant from the heating radiators with a two-pipe design, a parallel supply pipeline is laid. It must be connected to the bottom of the boiler.

- For systems with forced circulation of the coolant, an electric pump must be provided. It can be installed at any convenient location. Most often, the pump is mounted near the boiler, near the entry or exit point.

Connecting a heating radiator is not such a complicated process, if you approach this issue scrupulously.

Two-pipe heating systems: schemes and do-it-yourself installation

The use of two-pipe heating systems, pros and cons, varieties. Assistance in the selection of pipes by diameter, do-it-yourself installation of the system.

Arrangement of a two-pipe heating system

According to statistics, over 70% of all residential buildings are heated by water heating. One of its varieties is a two-pipe heating system - this publication is devoted to it.

Radiator on a two-pipe circuit

The article discusses the advantages and disadvantages, diagrams, drawings and recommendations for installing a two-pipe wiring with your own hands.

Differences between a two-pipe heating system and a one-pipe

Any heating system is a closed circuit through which the coolant circulates. However, unlike a single-pipe network, where water flows to all radiators in turn through the same pipe, a two-pipe system involves dividing the wiring into two lines - supply and return.

The two-pipe heating system of a private house, in comparison with a single-pipe configuration, has the following advantages:

- Minimal coolant losses. In a single-pipe system, the radiators are alternately connected to the supply line, as a result of which, passing through the battery, the coolant loses temperature and enters the next radiator partially cooled. With two-pipe configuration, each of the batteries is connected to the supply pipe by a separate outlet. You get the opportunity to install a thermostat on each of the radiators, which will allow you to control the temperature in different rooms of the house independently of each other.

- Low hydraulic losses. When arranging a system with forced circulation (necessary in large buildings), a two-pipe system requires the installation of a less efficient circulation pump, which allows good savings.

- Versatility. A two-pipe heating system can be used in a multi-apartment, one or two-story building.

- Maintainability. Shutoff valves can be installed on each branch of the supply pipeline, which makes it possible to cut off the coolant supply and repair damaged pipes or radiators without stopping the entire system.

Two-pipe heating system

Among the disadvantages of this configuration, we note a twofold increase in the length of the pipes used, however, this does not threaten a cardinal increase in financial costs, since the diameter of the pipes and fittings used is smaller than in the arrangement of a single-pipe system.

Classification of two-pipe heating

The two-pipe heating system of a private house, depending on the spatial arrangement, is classified into vertical and horizontal. More common is the horizontal configuration, which involves connecting radiators on a floor of a building to a single riser, while in vertical systems, radiators from different floors are connected to a riser.

The use of vertical systems is justified in a two-story building. Although this configuration is more expensive due to the need for more pipes, with vertical risers, the possibility of air pockets inside the radiators is eliminated, which increases the reliability of the system as a whole.

Also, a two-pipe heating system is classified according to the direction of movement of the coolant, according to which it can be direct-flow or dead-end. In dead-end systems, the liquid circulates in different directions through the return and supply pipes, while in direct-flow systems, their movement coincides.

Depending on the method of transportation of the coolant, the systems are divided into:

- with natural circulation;

- with forced circulation.

Heating with natural circulation can be used in one-story buildings with area up to 150 squares. It does not provide for the installation of additional pumps - the coolant moves due to its own density. A characteristic feature of systems with natural circulation is the laying of pipes at an angle to the horizontal plane. Their advantage is independence from the availability of electricity, the disadvantage is the inability to adjust the rate of water supply.

In a two-story building, a two-pipe heating system is always carried out with forced circulation. In terms of efficiency, this configuration is more efficient, since you get the opportunity to regulate the flow and speed of the coolant using a circulation pump, which is installed on the supply pipe leaving the boiler. In heating with forced circulation, pipes of relatively small diameters (up to 20 mm) are used, which are laid without a slope.

Which heating network layout to choose?

Depending on the location of the supply pipeline, two-pipe heating is classified into two varieties - with upper and lower wiring.

The scheme of a two-pipe heating system with an upper wiring involves the installation of an expansion tank and a distributing line at the highest point of the heating circuit, above the radiators. Such laying cannot be performed in a one-story building with flat roof, since the accommodation of communications will require an insulated attic or a specially designated room on the second floor of a two-story house.

Bottom wiring system

A two-pipe heating system with a lower wiring differs from the upper one in that the distributing pipeline in it is located in the basement or in an underground niche, under the radiators. The extreme heating circuit is a return pipe, which is installed 20-30 cm lower than the supply line.

This is a more complex configuration that requires the connection of an upper air pipe, through which excess air will be removed from the radiators. In the absence of a basement, additional problems may arise due to the need to install the boiler below the level of the radiators.

Top wiring system

Both the lower and upper circuits of a two-pipe heating system can be performed in a horizontal or vertical configuration. However, vertical networks, as a rule, are carried out with a lower wiring. With this installation, there is no need to install a powerful pump for forced circulation, because due to the difference between the temperatures in the return and supply pipes, a strong pressure drop is created, which increases the speed of the coolant. If, due to the peculiarities of the layout of the building, such laying is impossible, a highway with an upper wiring is equipped.

The choice of pipe diameter and the rules for installing a two-pipe network