Greenhouse made of polyethylene pipes. Do-it-yourself greenhouse made of plastic pipes. Choosing a location for a greenhouse

Plastic pipes serve as a good basis for creating a greenhouse in the garden. The material is available and easy to install. Making a greenhouse from pipes is easy, if you take into account the assembly technology.

Features of plastic pipes

Polymer pipes are intended for organizing water supply communications, but are often used to create various structures. The material is effective for the construction of greenhouses of various shapes and sizes. This is due to a set of advantages of PVC pipes compared to other materials.

To create a greenhouse, ordinary plastic pipes are used, which should not be confused with metal-plastic products. The former are made entirely of polymer material, while the latter have an inner layer of metal. It is possible to make a greenhouse from semi-metallic pipes, but it is more cost-effective and efficient to build a structure from ordinary plastic elements. The advantages of greenhouse material are as follows:

- simple installation technology, easy maintenance of the pipe structure;

- low cost, practicality, easy greenhouse repair;

- long service life and resistance to moisture and rot;

- the ability to create a greenhouse of any shape;

- Possibility of attaching different coatings.

PVC pipes are easy to install and create durable structures. The advantages of the material make it popular in gardening, but before use it is worth considering the disadvantages. The main negative characteristic is the low weight of the pipes, which makes the structure unstable. To make the greenhouse more reliable, weighting is used.

Structures that are too long with many connections will be unreliable, since the pipes will not withstand strong mechanical loads. It is important to select a material with optimal parameters, that is, a suitable diameter and wall thickness. This way, plastic pipes for a greenhouse will become a good basis, and installation will not cause difficulties.

Preparing for work

Before creating any design, preparation is necessary, including important points. This allows you to make the greenhouse reliable and durable, improve it performance characteristics and efficiency for growing horticultural crops.

One of the mandatory stages of installing a greenhouse from plastic pipes is a drawing. The diagram of the future product reflects all dimensions, structural elements, types of connections of greenhouse elements.

To create a diagram, you need to determine the shape of the product. From plastic pipes you can create single or gable structures similar to greenhouses. A lightweight arched greenhouse is a universal solution for small garden plot. The frame of the selected shape is shown in the drawing, and each component element has designated dimensions. A large greenhouse requires the creation of a simple foundation, which is also shown in the diagram. For small structures measuring less than 1x1.5 m, there is no need for a foundation.

The length of a greenhouse made of PVC pipes often does not exceed 2.5 m, and the height is about 1.8 m. A width of 1.5 m is optimal, but the structure may have smaller parameters. The size depends on the area of the intended installation site, the characteristics of the plants being planted and the ease of caring for them.

Selection of PVC pipes for a greenhouse

The quality of plastic pipes is the main requirement for creating a greenhouse. Products with a diameter of 25 to 38 mm are suitable for the installation of garden structures. To work, you also need connecting corners and adapters, with the help of which the elements are connected at the desired angle. The diameter of these parts must correspond to the parameters of the pipes used.

The color of the material does not matter. White products are often used as they are the most common. When purchasing, you should make sure there are no damage, cracks or dents on the pipes. It is worth considering that the greenhouse must be collapsible, and this requires screws to connect the elements.

Material calculation and tools

To calculate the amount of material required for an arched small greenhouse, you should determine the length of each arch, and then multiply the number by the number of arches. And also necessary wooden boards to strengthen the structure. They are located along the perimeter of the greenhouse, that is, you need two boards equal to the length of the greenhouse, and two equal to its width. Screws and fittings are selected with reserve.

To work, you will need simple tools, since installing plastic pipes with your own hands does not require professional skills. The set of tools for work includes:

- tape measure, building level;

- screws, nails, hammer;

- welding machine for plastic pipes;

- hacksaw for metal.

Frame a simple greenhouse made of pipes, consists of arches and a wooden base. For larger greenhouses, additional frame elements and a stronger foundation are required. Therefore, it is easy to make a small greenhouse for one bed with your own hands without a drawing.

Instructions for building a greenhouse

Making a simple and small greenhouse from plastic pipes is easy, but it is important to take into account the installation technology. The scope of work is as follows:

- Wooden boards are cut according to the length and width of the future greenhouse. The elements for the base are fastened with nails and installed on the ground.

- PVC pipes for arches are cut to the required length, and then bent one by one and attached to the frame with self-tapping screws. There should be equal spaces between the arches.

- If necessary, you can connect the arches at the top of the frame with a wooden lath or a plastic straight pipe. After this, a covering, for example, a film or non-woven material, is laid and fixed on the greenhouse.

From plastic pipes you can create both a small greenhouse and a large greenhouse. In the first case, the technology is simple, and the structure is easily assembled and dismantled. winter period. A large greenhouse requires a welding machine to connect pipes with fittings, as well as an accurate drawing.

Video: installation of a small greenhouse made of PVC pipes

Small greenhouses made of plastic pipes consist of a frame covered with film. This makes it easy to make your own shelter for plants.

You can easily make a greenhouse from plastic pipes yourself, since this material allows you to build structures of any shape and size. It will be a lightweight but durable collapsible or stationary structure with sheathing made of ordinary polyethylene or polycarbonate. In this article we will provide you with information on how to build such a greenhouse with your own hands at the lowest cost in one or several days.

Advantages and disadvantages of the material, types of structures

Plastic hot water pipes can be used not only for their intended purpose - installation of water supply or heating, but also for the manufacture of various lightweight and durable greenhouse structures.

The disadvantages include the fact that during thermal welding, the structure cannot be completely disassembled without damaging the integrity of the greenhouse frame. Under great physical stress, the pipe can bend and even break.

Types of greenhouses

There are several modifications of greenhouses made of plastic pipes:

- Arched type with polyethylene coating;

- WITH gable roof with polyethylene coating;

- Arched type with polycarbonate casing;

- With a gable roof with polycarbonate sheathing.

Preparation for construction: drawings and dimensions

Before starting to build a greenhouse, it is necessary to resolve the issue of installing the foundation. If the greenhouse is needed only in certain months, then a capital foundation will not be required. We will make a wooden base.

You will need to choose a convenient and level place in the garden, making sure that the soil does not sag under the weight of the greenhouse. To cover the frame made of plastic pipes we will use polyethylene film.

Dimensions of the arched greenhouse:

- By bending the pipe 6 meters, we get the correct arc;

- The width of the greenhouse is 3.7 meters, height - 2.1 meters, length - 9.8 meters;

- When purchasing plastic pipes, pay attention to the manufacturer. Czech and Turkish companies offer high-quality pipes. If you want to save money, you can buy Chinese or domestic products.

- For strength, you need to take pipes intended for supplying hot water, with a wall thickness of 4.2 mm (inside diameter 16.6 mm and outside diameter 25 mm).

- Connecting fasteners made of thermoset - wall thickness 3 mm.

- We take fittings in accordance with the diameter of the pipes to ensure the strength and rigidity of the structure.

Calculation of the required amount of material and tools for work

- Four boards with a section of 2x6 cm - 5 meters;

- Two boards with a section of 2x6 cm - 3.7 meters;

- Fourteen boards with a section of 2x4 cm - 3.7 meters.

- Six-meter plastic pipe with a diameter of 13 mm - 19 pieces.

- Three-meter fittings with a diameter of 10 mm - 9 pieces.

- Six-millimeter polyethylene film - size 6x15.24 meters.

- Wooden pieces of slats 1.22 m long - 50 pieces.

- Screws or nails.

- Fastenings (can be used for drywall).

- Butterfly hinges for doors - four pieces and two handles.

For the sides of the greenhouse:

From five beams 2x4 cm (length 3.7 m) it is necessary to make a frame for the sides of the structure:

- 11’8 3/4” = (2 beams) 3.6 m;

- 1’6” = (4 bars) 0.45m;

- 4’7” = (4 bars) 1.4m;

- 5’7” = (4 bars) 1.7m;

- 1’11 1/4” = (8 bars) 0.6m;

- 4’1/4” = (2 bars) 1.23m;

- 4 bars 1.5 meters long;

- 4 bars 1.2 meters long.

Tools for work:

- Hammer;

- Grinder and hacksaw for metal;

- Screwdriver or set of screwdrivers;

- Hand, electric or gasoline saw;

- Construction level and tape measure.

DIY greenhouse made of plastic pipes: assembly steps

- To construct the base, we cut each reinforcement rod into 4 pieces. You should get 36 pieces of 75 cm each. To fix the pipes we need 34 pieces. We divide two segments into two equal parts and get 4 rods of 37.5 cm each.

- From 2x6 cm boards we lay out the base of a rectangular greenhouse 3.7x9.8 meters. We connect the frame with screws or knock it down with nails. After making sure that all the angles are 90°, we fix pieces of reinforcement 37.5 cm long into them.

- To construct a frame from pipes, you need to take 34 pieces of rod (75 cm) and hammer them at the same distance (about 1 meter) along the two long sides of the base of the structure parallel to each other, 17 pieces each. At the top there should be rods 35 cm long.

- Next, we put 17 plastic pipes onto the reinforcement stakes driven in on both sides, bending them into an arc. We get a preliminary greenhouse frame.

- We fasten the plastic pipes to the wooden base with metal plates using self-tapping screws and a screwdriver.

- To install the end, it is necessary to assemble a structure from beams, as shown in the photo below. Install them into the greenhouse frame and connect them to the base with screws.

- From a 2x4 cm beam we cut out 4 pieces 70 cm long. At one end of each beam we make an angle of 45°. These bars are designed to strengthen the ends. To do this, we fasten the end frame to the base, as in the photo below.

- After we have made the frame, we need to make a stiffening rib at the top of the structure. To do this, you need to connect two pipes of 6 meters each with a plastic connector, and cut off the excess to get a length of 9.8 meters. We secure the pipe using special ties to the central part of each of the 17 arcs.

- Cover the greenhouse with plastic film. The entire greenhouse should be completely covered with film with a large overlap on the sides and length. On the larger side of the greenhouse, the film must be secured with prepared slats, nailing them to the base.

- Then pull it well and secure it on the other side as well. We recommend starting to attach the film from the middle, gradually moving to the sides.

- Advice: if you fix the film at a positive temperature, then in the future it will stretch and sag less.

- On the sides, you need to pull the film down, carefully fold the excess into convenient folds, moving from the center to the edges, and nail it to the base with slats. Where the door is located, you need to cut a square for the opening, leaving allowances for fastening of about 5–10 cm. We wrap the film behind the opening and fasten it inside the greenhouse with nails or self-tapping screws.

- Before final installation of the doors, it is necessary to check the actual dimensions of the opening, as they may turn out slightly different, and the door itself may not fit in size. To assemble the doors, you need to cut bars with a cross-section of 2x4 cm (4 bars 1.5 meters long and 4 bars 1.2 meters long). Make two frames out of them. You need to nail a beam diagonally for rigidity. We fasten the hinges to the opening with self-tapping screws. Doors should be on both sides of the greenhouse.

- The remaining film will go on the doors. It must be pulled over the frames of two doors and secured with wooden slats. There should be a film reserve of 10 cm on all sides.

- We screw the handles and put the doors on the hinges.

Second version of ends

- You can make the ends of the greenhouse from a sheet of fiberboard, chipboard or OSB. The wooden frame of the ends remains the same. Before covering the greenhouse with polyethylene, it is necessary to cut out elements from the selected sheets, as shown in the photo. We take measurements on site.

- At the bottom we attach the sheets to the wooden base and on the sides to the frame using self-tapping nails. At the top you need to take long 6-meter pieces of foam rubber or other soft material and fasten together with them the first pipe of the structure and wooden ends. We do this using self-tapping screws so that the ends do not fall off in the future.

- Then we stretch the film onto the greenhouse in the same way as in the first case, but now we do not give a large allowance at the ends. We secure it with slats. We install doors.

Greenhouse made of plastic pipes coated with polycarbonate

Polycarbonate is one of the most best options coating that will last for many years. This material is resistant to temperature fluctuations, has good thermal insulation properties, does not burn, and protects plants from UV rays.

The location for the greenhouse should be level and fully illuminated by the sun. If you will use the greenhouse in winter, then you need to install a heating system. It is not rational to build a large greenhouse, since it will be difficult to maintain the required microclimate in it. The height of the structure should be no more than 2 meters. The width of the frame is selected depending on the number of seedlings.

Materials

- Plastic pipes (for hot water supply).

- Boards 10x10 cm.

- Beam - 2x4 cm.

- Polycarbonate sheets.

- Reinforcement - length 80 cm.

- Plastic tees.

- Metal staples, plastic clamps.

- Construction cord.

- Self-tapping screws, screws, nails.

- Sand, waterproofing material(ruberoid).

Parts for doors and windows

Tools for work

- High level of construction.

- Long tape measure 10 meters.

- Jigsaw.

- Knife for cutting plastic pipes.

- Electric or cordless screwdriver.

- Electric drill.

- Set of drills.

- Hammer.

Stages of assembling a greenhouse from plastic pipes and polycarbonate

- For the base, we take a 10x10 cm beam and treat it with antiseptic agents. We make blanks: two beams 3 and 6 meters long. We connect them into a rectangle using metal staples or self-tapping screws.

- We dig a trench under the base. We mark the perimeter with pegs and stretch the cord around the entire perimeter. To control the correctness of the angles, we also stretch the cord diagonally. Their length should be the same.

- The depth of the trench should be about 5 cm so that the timber is not completely buried in the ground. Sprinkle a small layer of sand at the bottom of the trench. We cover the beams with roofing felt and lower them into the trench to avoid contact of the tree with wet soil. We overlap the waterproofing. We fill the remaining space with earth and compact it well.

- We cut the reinforcement into 14 rods about 80 cm long. We drive them along both long sides of the frame to a depth of 40 cm in increments of 1 meter. The rods must be located strictly opposite each other.

- We put pipes on the fittings, creating an arch. We fix them to the base using staples or clamps with self-tapping screws. We fasten the stiffening rib from the plastic pipe at the top with plastic tees, which must first be machined so that the pipe passes through them. Then the tees can be secured with self-tapping screws and the greenhouse will be collapsible.

- At the ends we make a structure for installing doors and windows. We make blanks of the required size from plastic pipes. We connect them using corners and tees into the structure shown in the drawings.

- To make hinges, we take a piece of pipe 10 centimeters long with a diameter of 1-1/4. We glue them together with PVC pipe glue and fasten them to the frame with screws.

- We make the latches from the same piece of pipe, cutting off a fourth of it and cleaning the edges. We install the doors and windows on the sides of the greenhouse and secure them with latches or screw them with self-tapping screws.

- To cover a greenhouse with polycarbonate, you need to know several nuances: the fasteners are placed in increments of 45 mm, the sheets are mounted end-to-end and connected with a special fastening - a strip (or overlapped by several millimeters), holes are drilled 1 millimeter larger than the diameter of the screws. Sealed thermal washers are placed under the screws, the sheets are placed so that the cells are positioned vertically, the protective film is removed after final installation, and the corner lines are fastened with a special profile.

- Polycarbonate should only be stored in a dry room with low humidity.

- Before laying polycarbonate on the structure, it is necessary to cover the ends with perforated tape and a side profile, which provides drainage and air circulation in the sheets so that condensate flows freely from the channels. We lay polycarbonate sheets with the protective film facing up. Otherwise, the material will quickly collapse.

Note to summer residents

- If the weather outside is too hot, then the doors of the greenhouse on both sides of the ends must be opened for ventilation.

- In the northern regions of the country, where there is heavy snowfall, it is necessary to remove the polyethylene for the winter, as it can stretch or tear greatly. Snow also perfectly protects the soil from freezing, helps retain nutrients in it and nourishes the soil with moisture.

- If you do not remove the film, then you need to put strong supports in several places of the frame.

- Instead of polyethylene, you can use durable film such as lutrasil, agrotex, agrospan, reinforced or bubble. The 11 mm thick reinforced film can withstand the weight of wet snow, hail and strong gusty winds.

- Light-stabilized polypropylene with aluminum reinforcement is resistant to thermal deformation and UV radiation.

- If possible, the area under the greenhouse should be concreted so that the wooden base does not stand on open ground, if you will keep seedlings, and then large plants, in special boxes.

- The service life of plastic pipes indoors is about 50 years. They will last about 20 years outdoors.

- All wooden elements must be treated with antiseptic agents.

Video: making a greenhouse from plastic pipes coated with polycarbonate

Video: how to make a greenhouse from plastic pipes and polyethylene covering

Video: how to build a greenhouse from plastic pipes coated with polycarbonate

https://youtube.com/watch?v=FezdC-E2iu8A greenhouse in your country house will allow you to always have fresh vegetables and herbs. On your desk all year round There will be salads made from fresh tomatoes and cucumbers. You can build a strong and reliable greenhouse with your own hands at minimal cost, since you don’t have to pay craftsmen for work or buy finished design for a lot of money, but only for plastic pipes, several wooden blocks and plastic film.

In high latitudes, where nature has given vegetable and berry crops too little time to grow and ripen, the summer season begins with the construction of a greenhouse. And the construction of a greenhouse, in turn, begins with the search for suitable material. And the first thing that comes to mind is plastic pipes, which seem to be specially created for this purpose. Let's see how you can quickly and easily build a greenhouse on your summer cottage using PVC pipes and the like.

Greenhouse made of PVC pipe: advantages and disadvantages

These are the reasons why a plastic pipe can be considered very suitable material for setting up a greenhouse:

- It has a low cost.

- Very easy to cut and drill.

- It can bend, and no special equipment is needed for this - hand strength will be enough.

- It is lightweight, making it easy to deliver and install.

- Pipes and parts (angles, tees) can be welded using slight heat.

- Plastic does not corrode or rot.

The only disadvantage is that plastic pipes are not very strong, so they cannot withstand heavy loads.

Preparing for construction

Let us note, just in case, that we are talking specifically about a greenhouse. A greenhouse, which is a year-round capital structure with heating, lighting, glazing and a foundation cannot be built from low-strength PVC and other plastic pipes. For these purposes, you should use a PVC profile, the same as that used for the manufacture of metal-plastic windows.

During the preparation phase, you need to consider the following questions:

Greenhouse design

Typically, you choose between two options:

In the case of plastic pipes, the first option is definitely preferable. You can verify this with a simple experiment. If you lay a half-meter piece of PVC pipe horizontally on two supports and lightly press it, it will bend relatively easily. If we repeat the experiment with the same segment, bending it in an arc and installing it between the supports so that it cannot straighten, you can see that the product can withstand much greater loads without the slightest deformation.

The greenhouse-house is assembled from straight sections of pipes, therefore, it is highly likely that they will begin to bend under loads from the wind. The arched design will show much greater durability. In addition, this version of the greenhouse has a streamlined shape, which means the load from the wind blowing in any direction other than longitudinal will be less.

Dimensions

The height of the greenhouse should be such that it is convenient to work in it. But it must be remembered that arched design width and height are linked - the first parameter will always be twice the size of the second. Therefore, you immediately need to estimate whether a structure with a given height will fit in the area allocated for it.

The greenhouse should not be greatly underestimated either. After all, its height gradually decreases from the center to the edges and for plants growing near the walls it may not be enough.

It is not advisable to make the greenhouse too wide, since it will be too high. It is better to install two greenhouses nearby.

If you plan to use cellular polycarbonate as a covering, then the length of the arch will have to be limited in accordance with the length of the polycarbonate sheet. But this does not cause any inconvenience: on sale you can find sheets of cellular polycarbonate 6 m long, which allows you to build an arched greenhouse almost 2 m high.

There are no restrictions on length. It is only desirable that it be a multiple of the step between the arches - for aesthetic reasons. It is believed that it is best to install arches no further than 50 cm from each other, but as can be seen from messages on the Internet, greenhouses with a step between arches of even 90 cm turned out to be quite viable.

Selecting a location and preparing the soil

The most preferable position of the greenhouse is when one side faces strictly south.

It is good if the structure is not in the open sun all day long, but is in the shade for at least a couple of hours in the afternoon - this mode is considered the most useful for plants.

The soil at the construction site must be leveled and fertilized with humus.

For reference. The correct name for the structure described here is “cold nursery”. It is installed in late spring, when it is already relatively warm outside.

A real greenhouse is laid in early March as follows:

The earth in this place becomes warm and literally soars, which is why the structure is called a greenhouse. After some time, when the manure rots (usually by the end of March), the straw mats are removed and cabbage is planted in the ground, and a little later - tomatoes and other crops. Only cucumbers can be planted on fresh manure - this is the kind of fertilizer that this vegetable likes most.

Choice of coverage

You can cover the greenhouse with one of the following materials:

- polyethylene film (reinforced is the most durable);

- air bubble film (has increased thermal insulation properties);

- cellular polycarbonate;

- agrofibre;

- agrofabric.

In the vast majority of cases, dense polyethylene film is used.

It is impossible to glass a greenhouse made of PVC pipes, since the weight of the coating will be too large for them.

Although the greenhouse is a primitive structure, it is highly advisable to sketch out a drawing of it at the design stage. So, firstly, it will be easier to calculate the amount of materials required, and secondly, minor flaws will appear in the drawing that would be overlooked during abstract design.

What PVC pipes should I use?

To build a greenhouse you need to take pipes with a diameter of 20, 25 or 32 mm. They have sufficient strength and at the same time bend relatively easily. Unlike polypropylene, PVC is not afraid of ultraviolet radiation, so there is no need to look for a special type of pipe for outdoor installation.

List of materials and calculation of their quantities

This is what our greenhouse will consist of:

PVC pipe

Each arch will consist of 2 pipe sections, the length of which is determined by the formula:

L = 0.25*3.14*D,

Where D is the width of the greenhouse.

The number of arches is determined by the formula:

N = (A/p) + 1,

A is the length of the greenhouse;

P - step between arches.

Additionally, you will need several pieces of pipe to install a ridge girder (it adds rigidity to the structure). The length of each of them is equal to the size of the step between the arches, the number is the number of spans between the arches.

You will also need 4 pieces of pipe, the length of which is equal to the height of the greenhouse - they are needed to arrange the door and window openings.

As an example, we will show the construction of a greenhouse measuring 3.8 x 6.3 m, in which the arches will be arranged in increments of 90 cm. The length of the pipe sections from which the arches will be assembled will be:

L = 0.25*3.14*3.8 = 2.983 m, take L = 3 m.

A total of arches will be installed:

N = (6.3 / 0.9) + 1 = 8.

For the ridge run you will need to prepare 7 pieces of pipe 90 cm long.

For arranging openings - 4 sections of 1.9 m each.

Pipeline details

In addition to the pipes you will need:

- straight tees: 2 pcs.;

- oblique tees: 4 pcs.;

- crosspieces: quantity N - 2, for our example - 6 pcs.

Board 50x100 mm

The total length of the boards should be equal to the perimeter of the greenhouse. In our case: 6.3*2 + 3.8*2 = 20.2 m.

Other materials

For the construction you will need metal pins 70 cm long with a diameter equal to the internal diameter of the PVC pipe used - two for each arch plus 4 more pieces. for arranging openings. In our case - 2*8 + 4 = 20 pcs.

You can't do without coverage. If film is used, then its width should be equal to the length of the arch, that is, 2L, and its length should be the length of the greenhouse + two of its heights.

For our example, we need a film with a width of 2 * 3 = 6 m and a length of 6.3 + 2 * 1.9 = 10.1 m. The total area (in case of making a coating from several fragments) will be 6 * 10.1 = 60.6 sq. m.

In addition to the above, you will need:

- Hardware: screws and nails.

- Steel strip.

The number of PVC pipes and corners for making doors and windows depends on the size of the panels.

Tool

To carry out the work, a home craftsman should have the following in his arsenal:

- hammer;

- screwdriver or Phillips screwdriver;

- hacksaw for metal;

- a device for welding PVC pipes (commonly called a “soldering iron” or “iron”): in some stores such a device can be rented;

- roulette;

- building level.

If you couldn’t get a soldering iron or there is no electricity in the area, PVC pipes can be connected to each other and to tees using special glue (cold welding).

Making a greenhouse with your own hands: step-by-step instructions

The construction process consists of the following operations:

Note. In the absence of tees and crosses, the ridge purlin can be screwed to the arches with plastic clamps. In this case, both it and the arches can be made from entire sections of pipes.

At one of the previous stages, two pins were driven into the ground along each end. Now you need to do the following:

- Using a plumb line, a point on the arch lies strictly above the pin is determined. We perform this operation for each of the 4 end pins, marking the found points with a marker.

- Now you need to take pieces of PVC pipe, which, as the reader remembers, were prepared for arranging the openings, and cut each of them so that, when put on the end pin, it almost reaches the arch.

- Next, each of the mentioned segments must be welded to the outlet of the oblique tee.

Where the window and door are supposed to be made, holes are cut out in the film, after which its edges are screwed with self-tapping screws and washers to the frame of the opening.

If you want to cover the greenhouse with cellular polycarbonate, do the following:

- Nail bars with a thickness equal to the diameter of the pipes to the wooden frame in the spaces between the pipes.

- Screw polycarbonate sheets to these bars using self-tapping screws with thermal washers. In order for the plastic to expand freely when heated, the diameter of the mounting hole must be 2–3 mm larger than the diameter of the screw.

- Carefully bend the sheet so that it goes around the frame of the greenhouse and screw it to the frame on the opposite side.

Making windows and doors

The door leaf and window are made in the form of a frame made of PVC pipe and 90-degree bends (corners), which is then covered with film.

Door and window hinges can be made from short pieces of larger diameter PVC pipe that can be loosely placed over the frame pipe.

That's it, the work is completed. You can plant the plants after a few days, when the greenhouse warms up.

The proposed design can be somewhat improved by replacing the short-lived wooden ballast with a concrete foundation. It doesn’t have to be made as a ribbon - a columnar version is also suitable. If there is a foundation, the metal pins are not driven into the ground nearby, but are embedded in concrete.

Video: homemade greenhouse made of plastic pipes

Having a greenhouse in your dacha or garden, you can start planting vegetable crops a little earlier than usual, so you won’t have to wait so long for a tasty harvest. The benefits are obvious, and the costs are minimal if you use such a cheap and easily processed material as PVC pipes. The tips outlined in our article will help you assemble a reliable design that will serve a cozy home plants and will be able to successfully withstand adverse weather factors.

You can build a greenhouse with your own hands from plastic pipes with ease and without large financial expenses. However, it doesn’t hurt to learn about possible nuances.

Advantages and disadvantages of plastic pipes

Every day, polymers are increasingly replacing wood, glass and other materials from the industrial sector. The plastic is durable and lightweight and is not corroded by mold. The material is not afraid of fumes, chemicals and moisture.

Plastic structures last longer than products made from other materials, as they can easily withstand negative environmental influences.

The disadvantage is the cost of greenhouses from manufacturers, as well as the sizes, which do not in all cases meet the needs of summer residents. However, there is no need to be upset, since you can build a high-quality greenhouse yourself.

The highest quality and most affordable are greenhouses with frame structure from profile pipes. However, if the budget is limited or there is no desire to overpay for the installation of such a greenhouse on the site, then you can build a structure from plastic tubes. This product has a number of advantages over more expensive analogues. The main advantages of the material include:

- Low cost. Aluminum buildings will cost much more.

- Easy to install and dismantle. This makes it possible not only to independently choose the dimensions of the structure, but also to dismantle it and store it in a garage in the winter. Without special skills, you can build a greenhouse from pipes in one day.

- Light weight. This quality is often mistaken by experts as the main drawback of the product.

- Mobility. The building can be easily moved from one place to another.

- Versatility of production. During the construction and design process, it is possible to choose any parameters and dimensions, taking into account the characteristics of the estate.

- Resistance to negative atmospheric influences.

- Long service period.

- Great appearance. You can build a structure yourself, the appearance of which will not be inferior to the factory product.

- Environmental friendliness. Plastic is a safe and environmentally friendly material. Accordingly, nothing will threaten the crop and soil.

The only drawback of plastic buildings is that factory-made structures are not always suitable for the available site. If you want to build a product of complex shape, then you should know that the structure will be unstable in gusts of wind.

Design dimensions

In most cases, two beds are placed in the greenhouse, which are separated by a path.

Beds in a greenhouse made of plastic pipes

The width of the beds is on average 0.9–1.1 m - this makes it possible to plant plants in two rows with the required spacing and provide unobstructed access to them.

The width of the path should be such that it is possible to move comfortably with a bucket and other dacha equipment, including a wheelbarrow.

Correct aisle width

The optimal width of the path is 0.7–0.8 m. In this case, the width of the structure will be 2.3–3 m.

The length of the product will depend on the needs and requirements for the location of the vegetables that are planned to be grown. Planting rates per 1 m2 can be seen in the table below:

Using the table you can determine the length of the building. Typically, structures with a length of 4–6 m are made, since it is impractical to install a greenhouse of smaller dimensions, and for buildings of greater length it will be necessary to use materials of increased strength. Construction technology will also differ.

It is important to know: if you plan to use polycarbonate as the material for covering the structure, then it is recommended to choose a length that is a multiple of the width of the sheets (2 m). In this case, you can avoid unnecessary pieces.

The height of the building should allow you to comfortably move around it. It is worth knowing that there should be at least 50 cm of free space above the plantings.

Correct greenhouse height

Warm air will accumulate in this place and air exchange will occur during the ventilation process. If you plan to grow low-growing vegetables, then a height of 1.9–2 m is sufficient. For tall crops, the minimum greenhouse height is 2.3–2.4 m.

The frame of the tube structure forms half a circle. The width of the product is the diameter of this parameter. If the diameter is known, then the radius can also be determined. The values allow you to calculate the length of the district. This can be done using the following formula:

L = 2πR = πD, where L is the circumference, R is the radius, and D is the diameter. The number π is 3.14.

For example, if you plan to make a greenhouse with a height of 200 cm, then with a correct arc the width should be 400 cm. In this case, the diameter of the circle is 400 cm and the radius is 200 cm.

Accordingly, the length of the district: L = 2 x 3.14 x 2000 = 12560 mm. Only half the circle is needed, so the length of the arc is calculated as follows: 12560 / 2 = 6280 mm.

The arc consists of 2 tubes and a cross, so the resulting value must be divided again: 6280 / 2 = 3140 mm. This will be the size of the pipe.

Drawing of a greenhouse made of pipes

There are many ready-made diagrams that will help you assemble a greenhouse yourself. If you choose a simple option, you can assemble the structure in a few days. The first step is to prepare a design drawing, with which you can easily calculate the required pipe footage. The volume of materials depends on the dimensions of the building.

The greenhouse assembly diagram includes the installation of sides for fencing.

An example of a drawing of a greenhouse made of plastic pipes can be seen in the figure:

Drawing of a greenhouse made of plastic pipes

The project must indicate:

- dimensions and shape of the product;

- methods of fixing elements;

- quantity necessary materials and fastening parts.

After drawing up the drawing, you can proceed to the selection of materials.

You will need to buy large-section plastic pipes from which the frame is made. In addition to the main frame parts, smaller diameter tubes will be needed. The elements will connect the main arcs with each other. This is necessary to give rigidity to the structure.

Plastic tubes can be easily cut, bent, glued and welded. In greenhouse production, polymer elements are often fastened with self-tapping screws, since liquid will not flow through the parts. The manufacturability of plastic makes it possible to implement projects of almost any complexity: from a greenhouse or a small arched greenhouse to a huge all-season product with a gable roof. You just need to first decide on the design and buy the necessary equipment and materials.

The following pipes are suitable for the manufacture of the structure:

All types of plastic pipes are sold with fittings, including:

- cross and tee splitters;

- swivel connectors;

- adapters for joining tubes of various sizes.

The use of fittings will speed up the process of construction work several times, but at the same time will increase financial costs.

Fittings for plastic pipes

It all depends on the capabilities and preferences of the owner. He must choose whether to use fittings or not.

To fix the frame, you will need metal rods 1.2 m long. Their diameter should be such that the rod fits freely into the tube.

Sides for fencing are made from edged boards. Recommended cross-section is 150 mm. The number of parts and length will depend on the dimensions of the greenhouse.

The transverse parts of the frame are fixed using plastic tees, which are used for plumbing. Another option is to use steel wire.

At the end, the structure will need to be covered with a reinforced polyethylene or polycarbonate film.

There is one more nuance that is important to consider before the start of construction work. A greenhouse made of plastic pipes can be stationary or portable. In the first case, the parts will need to be welded or glued; in the second, the elements are fastened with screws.

Greenhouse project made from plastic pipes

The choice must be made based on needs.

Calculation of the required amount of material

To calculate materials, you will need to know exactly the dimensions of the structure. It is also important to determine the distance between the arches. If the covering of the building is planned to be dismantled in winter, then the arches can be located in increments of 0.9–1 m.

Arch installation step

For a stationary structure, the step should be reduced to 0.6–0.7 m. This will protect the product from damage after heavy snowfalls.

It is important to consider the material for the construction of screeds, end walls, doors and windows. The total length of the longitudinal ties is calculated by multiplying the length of the greenhouse by the number of ties. Most often, at least 5 pieces are installed: two bottom, two side and one ridge. To strengthen the structure, it is recommended to install additional side ties.

The end walls will require pipes with a total length of 17–20 m. One door will require at least 5 m of pipe, and a window - 2.2–2.5 m. For convenience, you can make a detailed sketch, which will indicate all the dimensions and number of parts for fixation. An example can be seen in the image:

Diagram of a greenhouse made of pipes indicating the location of parts

As an example, we will consider a greenhouse of the following dimensions:

- length - 4 m;

- width - 2.4 m;

- height - 2 m;

- arc length - 3.8 m;

- the pitch of the arches is 0.67 m.

For the frame you will need pipes 6 m long and 25 mm in diameter. Such parts can ensure the reliability and rigidity of the structure. 25 mm fittings are used to fasten the tubes. You will also need glue.

List of materials that will be needed to build a greenhouse from plastic pipes:

- reinforcing bars;

- crosspiece for 25 mm tube;

- slats 50x100 mm;

- plastic pipes 25 mm;

- oblique tees;

- nails;

- metal strip;

- self-tapping screws;

- adhesive mixture;

- tees for pipes 25 mm.

For a greenhouse of these sizes with two doors and windows, materials will be needed in the following quantities:

- steel angle 90° with a diameter of 25 mm - 16 pcs.;

- plastic pipe 6 m long and 25 mm in diameter - 16 pcs.;

- wide tape or metal profile for connection (when using polycarbonate) - 1 pc.;

- two-plane tee - 4 pcs.;

- crosspiece - 5 pcs.;

- polycarbonate - 3 sheets measuring 2x6 m;

- single-plane tee with an angle of 90° – 28 pcs.;

- two-jaw clamps - 18 pcs.;

- self-tapping screws for fixing polycarbonate with thermal washers - 100 pcs.;

- furniture bolts for fixing side ties - 36 pcs.;

- single-plane tee with an angle of 45° – 4 pcs.;

- door hinges - 8 pcs.;

- self-tapping screws 24 mm - 48 pcs.;

- self-tapping screws 55 mm - 36 pcs.

Polycarbonate or film can be used as a coating material. If the second option is chosen, then approximately 8 linear meters of polyethylene are needed. with a width of 6 m.

Tools that will be needed:

- hammer;

- device for welding plastic tubes;

- hacksaw;

- building level;

- screwdriver or screwdriver;

- construction tape;

- hacksaw for metal.

- Desktop;

- ventilation system;

- heating boiler;

- racks;

- shelves;

- design for automatic watering;

- fluorescent light bulbs;

- thermometer with hygrometer.

After preparing the materials, you can begin site planning and construction work.

How to build a greenhouse from plastic pipes with your own hands - step-by-step guide

To eliminate the possibility of the building skewing during installation and use, the area under the greenhouse must be leveled.

Leveling the area for the greenhouse

To do this, you need to mark the location of the future structure on the ground using pegs and rope.

Marking the area using pegs

After this, the area should be checked with a building level. If there is a slope of more than 1°, then the area must be leveled.

A sand cushion 6–10 cm thick should be made under the base.

Determining the location for the structure

First of all, you need to determine the location on the site for the construction of the structure. It should be:

- in flat areas so that the frame can be easily mounted;

- have direct exposure to the sun's rays, otherwise the greenhouse will not have its main property;

- in open areas.

The main condition for the correct development of plants is light. This is especially true in winter and early spring. If the greenhouse is located in a place with insufficient lighting, then it will be necessary to install additional lighting fixtures.

Lighting fixtures in a greenhouse

It is worth understanding that this can lead to high costs of grown vegetables. To make a greenhouse, you need to choose the most illuminated area, which is located at a great distance from trees and buildings. It is important to protect crops from excess shade.

The placement of the greenhouse relative to the cardinal points is an important factor when determining the location. The most preferable option is to locate the building from the west to the east.

Location of the greenhouse relative to the cardinal directions

Only in this case can crop lighting be ensured from morning to evening.

If it is not possible to place the greenhouse in such a place, then the frame must be installed so that the sun's rays enter through the covering at the beginning of the day. The morning hours are the coldest, and if the sun does not warm the air in the greenhouse, many plants may stop growing and lose their ovaries.

If there is insufficient lighting, fungal diseases can develop. This often leads to crop loss.

Another important factor affecting the effectiveness of a greenhouse is its location in relation to prevailing winds. This is of great importance in the case of using a protective structure throughout the year. In winter, the presence of cold winds can increase heating costs several times. If you plan to place the greenhouse in an open area, it is recommended to build barriers that can protect from the wind. You can use a hedge or a wooden fence mounted around the greenhouse at a distance of at least 10 m.

Hedge for protection from wind

This placement will avoid creating a shadow.

It is best to place the structure next to a private house so that there is free passage in winter during snow drifts. The path must be made of hard surface. This will protect the product from dirt during rain. The width of the track is determined based on the size of the wheelbarrow.

Making the base

A frame will be used as the basis, which will be able to hold a light frame and maintain its geometry parameters. The choice of the required base option is not associated with the design or type of construction. It depends on financial capabilities and whether the product is stationary or portable.

To make a frame, you will need to prepare the following elements:

- board 6 or 8 mm thick;

- block 6x12 or 8x12 mm;

- rigid plastic pipe for the bottom trim.

The base is made of thick boards. If financial capabilities allow, it is recommended to use timber. The elements are fastened by cutting half a tree without using fasteners. Accordingly, the frame will not contain metal elements that could rust.

The base of the bars will need to be buried in the soil. To do this, you first need to dig a pit. Only fill the trench around the perimeter so that the bottom and walls of the pit are covered. Next, the frame is installed.

Wooden greenhouse frame

A frame buried in a trench will serve as a foundation, but it is worth understanding that such a foundation is not necessary for a seasonal structure.

A frame made of tubes cannot be an independent base. It is made if there is a foundation made of wood, brick or concrete. Fixed with staples to bars or anchor bolts fixed in concrete during the curing process.

If the foundation is made, then it will not be possible to move the structure. Therefore, it makes sense to consider the process of making a plank frame as a basis. Sequencing:

- First of all, you need to prepare a site for making a greenhouse. A layer of turf should be removed from the area so that the area is longer and wider than the structure being erected by approximately 1 m. This will allow for an indentation of 0.5 m on each side.

- The surface must be measured with a building level. If necessary, the site must be leveled. A difference of 5 cm is allowed over a period of 2 m.

- A frame should be assembled from four boards. You need to decide on the sizes in advance. The structure is fixed with several self-tapping screws or nails. The length of the fastening element is determined taking into account the thickness of the attached part: it should be 2.5 times the thickness of the rail.

- The frame must be measured diagonally in both directions with a tape measure. If the values coincide, then the base is smooth. If not, the flaws should be eliminated.

- The frame is installed and fixed by driving in reinforcing bars from the inside of the corner. The length of the rod is 75–80 cm. The sections are driven flush with the frame.

Visually, the process of constructing the frame can be seen in the image:

Construction of a greenhouse base

The base will be in contact with moist soil. Therefore, the material for production must be thoroughly dried. Before assembly, the parts must be coated with hot bitumen and an antiseptic.

Manufacturing of frame structures

The first step is to do the following:

- Along the long walls on both sides of the frame, you need to hammer in the rods with a sledgehammer so that no more than 40 cm remains above the base.

- A piece of plastic tube is placed on the fittings.

To make internal arcs, you need to connect 2 pieces of tube 3000 mm each by welding so that the cross is located in the center.

Installation of frame arches

For external parts, the tubes in the center should be connected not with a cross, but with tees.

The frame is assembled as follows:

At this stage, openings for installing windows and doors are prepared. Structures are needed for ventilation.

The two pieces of reinforcement that were installed earlier are places for installing windows and doors. Installation sequence:

- From the reinforcement that is driven in across the width, you need to draw a line up and make a mark on the outer arch.

- The tools you will need are: a flat piece of wood, a marker and a building level.

- Next you need to embed the oblique tees. You will need to measure the distance from the bottom of the reinforcing bars to the mark.

- You need to cut a piece of plastic tube to size.

- A tee is welded to the part so that a structure with a tee in the upper part is obtained. The bevel should mate with the tube.

- An arc is cut at the mark. The part is under load, so work should be done carefully.

- The tee is welded into the prepared space. It is recommended to carry out the work with an assistant.

After this, a door is made from tubes. The construction process can be seen in the diagram:

Making windows from pipes

Windows should fit into prepared frames without much effort.

As canopies, you can use pieces of plastic tube, but with a larger diameter. The 25mm tube should fit into the canopy easily.

How to cover a greenhouse with polyethylene or polycarbonate?

The next step is covering the greenhouse:

Covering the greenhouse with plastic film

The process is not complicated. To do this, attach the film to a wooden frame using nails and strips. The windows will also need to be covered with polyethylene and installed in their places. The following steps should be followed:

- The supply must be distributed evenly. At the ends there should be pieces of plastic film identical in size.

- The covering should be nailed through the boards to the frame.

- First of all, you need to nail the film along the long wall.

- You need to start from the middle of the surface, heading towards the corners.

- When the covering is stretched, according to this scheme it needs to be nailed to the second wall of the frame.

- In the end parts, the film is folded and then nailed.

In the covering that is fixed to the frame, you need to cut holes for doors and windows so that there is an overlap at the extreme parts of the holes for attaching the plastic film to the slats.

Greenhouse doors made of pipes

This method allows you to quickly make a budget greenhouse from plastic tubes. The principle of its structure is taken as the basis for many variations. The end parts can be made from plywood sheets, the dimensions of the door, the location and size of the windows can be changed, stiffeners can be mounted diagonally in the end parts, etc.

Fastening plastic film with a stapler

The reinforced film can be fixed using tube clamps. In the lower part it must be dug in with soil and strengthened by laying stones or slats on top.

If you plan to cover the greenhouse with polycarbonate, you will need to perform the following steps:

- Wooden slats need to be placed on the frame between the ribs.

- A solid surface is prepared. The ribs should be recessed inward.

- Holes are drilled into which fasteners will be installed.

- Polycarbonate is fixed with self-tapping screws. Be sure to install thermal washers.

Fastening polycarbonate with self-tapping screws and thermal washers

The diameter of the recesses in the polycarbonate should exceed the diameter of the screws by several mm. The gap is necessary to compensate for the expansion of the material due to atmospheric influences.

Products made from pipes are popular among summer residents. Many fans of year-round cultivation of vegetables are engaged in their production. Each owner has his own secret, which facilitates the construction process and reduces the cost of construction.

Some useful tips:

If you take these tips into account, you can make a high-quality greenhouse with your own hands.

Video: building a greenhouse

Any frame made of plastic tubes can be covered with plastic film or polycarbonate. The only material that cannot be used to cover a greenhouse of this type is glass.

With your own hands you can make a greenhouse that will delight you with fresh cucumbers, peppers, tomatoes, strawberries and herbs all year round. In order for the design to be of high quality, it is important to follow the instructions.

The gardening season has already arrived, and it’s time to think - buy or make a greenhouse from plastic pipes with your own hands? A greenhouse is a necessary thing in any garden if you grow something other than flowers and parsley. Tomatoes and cucumbers grow well in greenhouses. Moreover, if the greenhouse has a winter option, then they can grow there all year round.

But the better the quality of the greenhouse, the more expensive it is. In this case, you can try to make a greenhouse with your own hands. It can be made from different materials: someone makes a frame from metal, someone from wood.

Making a greenhouse with your own hands

But today we will look at a fairly simple option - from plastic pipes, which are used for plumbing, and sometimes for heating systems. These pipes are notable for the fact that they bend well. In addition, plastic is a universal material.

It does not suffer from rust, chemical fertilizers, or moisture. The only thing that can harm it is mechanical impact. But you’re not going to drop stones and concrete slabs onto the greenhouse, are you?

Materials and tools for making a greenhouse

In order to determine the materials, you need to decide what exactly your greenhouse will be made of, what size and configuration. In today's article we will look at the simplest greenhouse: arched configuration, one door, greenhouse film. But keep in mind that plastic pipes can also be used to make polycarbonate greenhouses, with additional ventilation (windows), with a gable roof, etc.

Materials:

- Plastic pipes (quantity and length are calculated based on the size of the greenhouse)

- Greenhouse film (thick)

- Fittings or any other metal pins that fit well into the pipe. The length of the reinforcement should be approximately 60-70 cm + 4 pins 70-80 cm long for corner fastenings

Frame boards

Also take into account the fact that the greenhouse described in the article is removable. Capital greenhouses are installed on a concrete, metal or wooden foundation, fixed in the ground.

Stages of greenhouse construction

Before you start assembling a greenhouse from plastic pipes with your own hands, you need to prepare a site for it.

Choose an area with a relatively flat surface, even though you will be leveling it. Remove the turf from the area of the future greenhouse + 0.5 m on each side. Now, using a construction spirit level, measure the surface and level it. Let's assume a difference of 5 cm with a distribution of 2 m.

Choose an area with a relatively flat surface, even though you will be leveling it. Remove the turf from the area of the future greenhouse + 0.5 m on each side. Now, using a construction spirit level, measure the surface and level it. Let's assume a difference of 5 cm with a distribution of 2 m.

Now we assemble the frame from boards adjusted to the size of the greenhouse. The boards need to be thick and durable. At the corners we fasten them with galvanized self-tapping screws (2-3 pieces depending on the size) 2.5 times longer than the thickness of the boards.

We check the assembled frame using a tape measure: measure the diagonals, if they are equal, then everything is fine, if not, look for errors.

We install the frame in the right place and secure it with long pieces of reinforcement or pins. The pins need to be hammered into the corners so that the structure does not move or dangle from side to side. There is no need to leave long parts of the pins; drive them into the ground to the level of the frame.

Advice from experienced gardeners: before installing the frame, treat wooden structure hot bitumen - this way it will last longer provided it is in constant contact with moist soil.

Now the base for the greenhouse is ready, you can assemble the frame

Mark the wooden frame in the places where the pipe arches will be. It is worth remembering that the more often they are installed, the stronger the structure will be. But you shouldn’t get carried away - 0.5-0.8 m between the arches is enough.

Drive pieces of reinforcement into the ground outside the frame at the marked locations. Their number is twice as large as the number of arches - the fastening will be on both sides. No more than 40 cm of the pin should stick out from the ground. The reinforcement should not be driven in flush to the frame; leave a small gap (about 1 cm).

Drive pieces of reinforcement into the ground outside the frame at the marked locations. Their number is twice as large as the number of arches - the fastening will be on both sides. No more than 40 cm of the pin should stick out from the ground. The reinforcement should not be driven in flush to the frame; leave a small gap (about 1 cm).

Now put the pipes on the pins. Buy for a greenhouse PVC pipes with a wall thickness of at least 3 mm. Secure the pipes at the base with metal mounting brackets to the wood base.

Install the stiffener. To do this, another pipe is fixed along the entire length of the greenhouse at the highest point above or below the arched pipes. It must be attached both to the end pipes and to all arched pipes. When building a simple greenhouse, the stiffener is secured with galvanized binding wire or plastic clamps.

The ends of the greenhouse are made of boards. First, a doorway (frame) is made in the middle, then additional structures are installed on both sides. You will get a design approximately like the one in the diagram (see figure). The number of boards may vary depending on the width and height of the greenhouse.

The frame is ready, it's time to start stretching the film. The film should be greenhouse, dense. Some gardeners recommend using 1.1 mm reinforced film. It will not tear even in a hailstorm. Cover the frame with film, evenly distributing the stock.

The frame is ready, it's time to start stretching the film. The film should be greenhouse, dense. Some gardeners recommend using 1.1 mm reinforced film. It will not tear even in a hailstorm. Cover the frame with film, evenly distributing the stock.

Check that the film completely covers the structure on all sides. There are two ways to fasten: wooden planks or a construction (furniture) stapler.

Better, of course, with planks. They do not need to be made from high-quality material; debris and remnants from the main work will do. But they must be strong and dry! The plank is applied to the film and nailed to the base frame with nails. In the end openings the film is wrapped on wooden frames and nailed exactly the same way.

All you have to do is make a door with a closing element (a simple latch is quite suitable) according to the size of the end door frame, cover it with film and hang it on the greenhouse.

Video - do-it-yourself greenhouse made of plastic pipes

As you can see, making a greenhouse from plastic pipes is not so difficult with your own hands, but you need to have some skill. Having practiced on a simple one, you can make a more reliable greenhouse from pipes with fastening fittings of any design and with any coating, including polycarbonate.

Are there mites in Pitsunda? Ticks in Abkhazia. Pitsunda pine grove

Are there mites in Pitsunda? Ticks in Abkhazia. Pitsunda pine grove Red viburnum (Viburnum opulus L

Red viburnum (Viburnum opulus L Nail Making Business How to Make Copper Nails

Nail Making Business How to Make Copper Nails Stone brazier: material features and manufacturing options

Stone brazier: material features and manufacturing options Blackroot medicinal cultivation

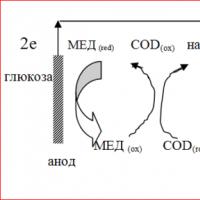

Blackroot medicinal cultivation Fuel cells: a glimpse into the future

Fuel cells: a glimpse into the future Houses with a hipped roof projects

Houses with a hipped roof projects