How to wire a solid fuel boiler. How to piping a heating boiler Do-it-yourself piping diagram for a gas heating boiler

Autonomous heating allows you not to depend on established consumption standards, the pricing policy of heat suppliers and their mood. This makes it possible to independently control the heating process and maintain the most comfortable temperature in the house, while saving resources.

And if you have installed a heating boiler piping with your own hands, then it will last longer and will take up less financial resources, isn’t it? But have you never engaged in tying, and the word itself seems incomprehensible to you at first glance?

Don’t be intimidated by the abundance of pipes, devices and technological steps - after reading the article you will be up to the task. Here we consider piping schemes for floor and wall types of heating equipment, select illustrative photos and recommendations from specialists for piping at home.

A heating boiler piping is a system of pipelines and equipment designed to provide radiators with coolant. Simply put, it's everything except the batteries.

The first step is choosing a heating boiler, the performance of which must be determined in advance.

The calculation of the required power of the heating unit is influenced by many factors, these are:

- volume of the building;

- number of windows and total glazing area;

- number and area of doorways;

- thermal conductivity of materials used in the construction of walls;

- degree of insulation of load-bearing structures;

- average annual temperature in the construction region;

- location of the building, i.e. Which side of the world faces the main, traditionally most glazed, façade?

However, there is an average indicator that, without in-depth calculations, allows you to determine the required performance.

For the middle zone, 1 kW per 10 m² of heated area can be taken as a starting point (but not a guide to action!). It is imperative to add a reserve of at least 20% to the design power of the heating boiler.

Heat for heating buildings is obtained by processing fuel in boilers that heat the coolant

Types of heating boilers

Conventionally, heating boilers can be divided into autonomous and manual loading.

Depending on the fuel used, autonomous boilers are:

- liquid fuel.

The order in the list determines the cost of heating depending on the type of fuel: gas boilers will be the cheapest to operate.

Image gallery

The tasks and purpose of boilers are clear to everyone. This is literally the “heart” of the entire heating system, without which the coolant simply will not warm up to the required temperature and provide comfortable living conditions. But in order for all the component elements of the unit to function fully, the heating boiler must be properly piping with polypropylene, diagrams and photos of which will be presented in this article.

Purpose of the strapping

The initial task for which heating boiler connection diagrams were developed was to protect all components of the heating unit from overheating and, accordingly, from breakdown. This ensures that all key performance characteristics heating apparatus.

Various circuit examples

The boiler piping, to put it quite simply, is everything that is located between the boiler/stove and the radiators. The functionality of the entire system and the rational use of finances depend on how correctly and in accordance with technical recommendations it is carried out. Important! A properly selected and implemented connection diagram for a heating boiler makes even a low-power unit work more efficiently, maximizing its energy resource to the heating main.

But it is even more profitable to wire the heating boiler yourself, because there is no need to resort to the help of specialized companies that provide similar services. Of course, if you do not have certain skills in this area of activity and are afraid that you will not be able to cope with the implementation of the task on your own, then it is still better to entrust the connection of the heating boiler. Believe me, sometimes it makes sense to overpay, because not everyone can assemble such a large thermal unit with their own hands without making mistakes, which can subsequently lead to a decrease in the quality of the equipment and its breakdown.

Classic version

.png)

Classic strapping pattern

Correctly performed piping of a gas or solid fuel boiler guarantees the efficient operation of the entire heating unit. In this process, it is necessary to pay special attention to such a point as adjusting the temperature conditions at the inlet and outlet of the thermal circuit. Thanks to this, it is possible to reduce the temperature difference to a minimum, which, in turn, results in the use of a minimum amount of fuel, and, as a result, a reduction in financial costs for their purchase.

First, until the water in the system reaches the required temperature, the coolant will be moved along an auxiliary line. After the temperature of the coolant corresponds to the value set by the thermostat, it will go into the main pipeline, through which the room will be heated.

Complete set of strapping diagram

.jpg)

What's included

Almost any boiler piping scheme involves the use of the following structural components:

- bypass valve;

- centrifugal pumping unit (circulation pump);

- valves of various configurations and purposes (drain, ball, etc.);

- expansion tank;

- a device for monitoring pressure in the system;

- pass filter;

- tees, connections, couplings, clamps;

- washers, nuts, bolts;

- valve set;

- or an automatic valve for bleeding air or a heating circuit.

In addition, you will also need a set of wrenches and welding machine, which, in the absence of one, can be easily rented at a hardware store.

Using a wall-mounted boiler

Components that are connected to a wall-mounted gas heating boiler must be lined up in a piping diagram. You can connect nodes on your own using three methods:

- hot water supply;

- floor hidden heating installation;

- running a heating circuit around the perimeter of the entire house.

If you are planning to equip your home with a single-circuit heating unit, then coping with the task will not be so difficult.

.png)

When piping the boiler with your own hands, you must strictly follow the diagram offered by the manufacturer of this device. Otherwise, even minor flaws made during the installation of the heating main can reduce the efficiency of the entire installation as a whole or, even worse, lead to a malfunction of the heating unit!

The piping scheme of a double-circuit heating boiler deserves special attention, since it can be either direct or mixing. The first option is characterized by temperature control via a burner, while in the second option, not only a burner is used for these purposes, but also a mixer with a tracking drive. And if you are far from all these subtleties, then it is better to entrust the process of constructing such a unit to professionals.

VIDEO: Connecting a gas boiler

What are emergency harnesses and what is their purpose?

Regardless of which heating boiler connection option you have chosen to furnish your home, any of them must be supplemented with an emergency circuit. It is thanks to the additional piping that your heating unit and the entire system as a whole will be able to fully function in the event that unforeseen emergency situations arise. As a rule, most often boilers stop working due to power outages.

So, today specialists with many years of experience in this field of activity offer 3 effectively working options for constructing emergency circuits.

Feeding the pump from an uninterruptible source

This method of ensuring uninterrupted operation is characterized by the use of battery devices or special uninterruptible power supplies. However, this option cannot always be implemented, since not every owner of such equipment regularly feeds it with electricity. Therefore, if you do not want to get into a difficult situation, do not forget to check the performance of the batteries and charge them from time to time.

.jpg)

An excellent solution would be a 12-volt circulation pump, which charges as long as there is electricity without disconnecting from operation, and when the mains is not working, it runs on battery power. It switches automatically, does not require any forced adjustment, is inexpensive, and works for a long time.

Natural circulation

In this case, the main heating main, which operates by artificially pressurizing the pump, is supplemented by another circuit, which operates through the natural circulation of the heat source. This system is connected immediately after the centrifugal pumping apparatus stops working. However, it is worth understanding that the natural way of moving hot water The system will not be able to fully heat a large room, so install it only in those rooms where there is a need to retain heat.

Design of a special emergency circuit

.jpg)

Bypass for the system

This option is the most optimal, but at the same time the most financially expensive. After all, its device will require another circuit that will work during non-standard situations.

Here, in fact, are all the subtleties of connecting the thermal circuit together with the heating element. We hope our tips will help you create the most comfortable temperature conditions for living in your home!

VIDEO: Heating a house - boiler piping diagram

Reading time: 5 min

The correct piping of a solid fuel boiler affects the efficiency of its operation and service life. Therefore, when choosing the optimal scheme, it is necessary to take into account a lot of nuances and features. In this case, the equipment will work efficiently and for a long time.

All wiring diagrams for solid fuel boilers

There are a large number of boiler connection schemes that are suitable for different conditions of use. An individual project is developed for each home, which indicates the important positions of the systems, taking into account the regulated requirements.

Closed system

If you want to organize an affordable but reliable piping scheme for a solid fuel boiler with a boiler, a closed option may be the most suitable. It operates due to the difference in the densities of cold and hot coolant and has the following advantages:

- Simplicity and accessibility of circuit installation.

- No difficulties in self-service.

- Long service life.

- Protection of pipes from corrosive processes.

Disadvantages include the inability to monitor temperature and a decrease in efficiency indicators due to the natural circulation of the coolant.

Closed system circuit

The closed circuit of connecting a solid fuel boiler with a battery tank prevents the negative effects of oxygen and deprives the owners of the building of the need to constantly monitor the volume of water. When arranging such a system, you should adhere to the following rules:

- The tank must contain at least 10% of the coolant volume.

- A safety valve must be installed on the supply pipe.

- The highest point of the equipment is equipped with an air vent.

Elements from the safety group, which include an air vent and valve, are purchased additionally - only flagship boilers have them in the basic set. The task of the safety valve is to discharge the coolant when the pressure exceeds the permissible level. The normal value is 1.5-2 atm. The emergency valve is activated when the level of 3 atm is reached.

The solid fuel boiler is also being wired and a pump is installed. This option is characterized by high heat transfer to the liquid, which increases efficiency values and makes the system energy efficient. Energy consumption for heating the liquid is reduced, and the need to install large-diameter pipes is eliminated, since hydraulic resistance is overcome due to the operation of the pump. As it heats up, the coolant does not evaporate, because it is contained in a sealed membrane. Closed option strapping protects equipment from corrosion and increases its service life.

The disadvantages include the system's dependence on the source of electricity and the high cost of installation. However, it will not be possible to carry out the installation work yourself.

Open system with natural circulation

Boiler design long burning(KDG) with open. The strapping scheme is in particular demand. This is explained by the fact that even with sudden changes in temperature or pressure, the equipment continues to operate without loss of tightness. At the same time, the operating efficiency does not depend on the power supply, since solid fuel material is immersed in the boiler.

The disadvantages of an open connection scheme for a solid fuel boiler include:

- Penetration of air into pipes, which contributes to the development of corrosion on their inner surface. To protect the system from the negative effects of oxygen, mineral oil is placed in the expansion tank.

- Rapid evaporation of the coolant, so its supply must be constantly replenished.

- Uneven temperature distribution at different points of the circuit.

But despite a number of disadvantages, the open installation scheme of a wood-burning or pellet boiler is popular. This is justified by the simplicity of its arrangement and affordable cost.

The scheme provides for the following elements:

- Thermometers. In addition to the sensors built-in by the manufacturer, additional ones need to be installed on the processing and supply pipes.

- Check valve.

- Expansion tank.

When tying with polypropylene, you need to place the pipe inlet 0.5 m below the location of the radiators to ensure free circulation of the coolant. The forward (supply) and return pipes are fixed at a certain angle. It is still necessary to carry out some calculations to assess the hydrodynamic resistance on all sides, and also try to reduce the number of reinforced elements.

Efficient and uninterrupted operation of the equipment depends on the installation location of the expansion tank - it is placed at the highest point of the heating circuit.

Forced circulation system

When tying a Stropuva boiler or any other model, it is necessary to consider the option of a circuit with forced circulation water. It involves installing pumping equipment on the supply or return pipeline, which increases the intensity of fluid movement. So, with natural circulation, the speed is only 0.1-0.3 m/s, and with a pump - 0.7-1 m/s, which contributes to many advantages:

- Possibility of reducing pipe diameter.

- Reduced warm-up time for radiators, lack of inertia.

- Convenient pipe laying options, long lines while maintaining optimal pressure.

- Minimal slopes of the routes, since the movement is carried out due to the operation of the pump.

- Possibility of installing an expansion tank in the boiler room.

There are other advantages, including the ability to interact with a heated floor system. Disadvantages include energy dependence, because... the pump operates on the basis of electrical energy.

To protect equipment from shutdown or explosion, it is necessary to arrange a safety group, which includes safety valves, uninterruptible power supplies and generators.

Another disadvantage of forced schemes is periodic noise. But such disadvantages are covered by a wide selection of heating schemes, which include:

- Single-pipe option.

- Double-circuit (Tichelman system).

- Collector.

- Warm floor.

Piping a boiler with a three-way valve: procedure and diagram.

Because the solid fuel boilers They do not operate continuously, but periodically; they are constantly exposed to moisture in the form of condensation, which leads to corrosive processes. The cooled water from the return flow is transferred to the heat exchanger and settles on its walls. To prevent negative consequences, you can use a three-way valve.

This is a regular adjustable valve with 2 inputs and 1 output. Receiving the appropriate signal, the valve opens the supply channel and eliminates the appearance of a dew point. When the system starts, the circulation of coolant in a small circle is suspended.

Three-way valves can also be used to change the temperature of the coolant that is sent to the consumer. In this case, the equipment is configured to work in the opposite direction, when the cold coolant from the return pipe moves to the supply pipe.

A system with a three-way valve ensures effective heating of the liquid in the boiler in case of inoperability or planned shutdown of radiators. When the temperature rises to the required values, the valve comes into operation again and returns the coolant to the heating system. If the boiler is used daily and year-round, this piping option will be highly effective.

Circuit with buffer capacitance

Due to poor controllability of boilers, owners need to constantly monitor fuel volumes and draft intensity, which causes a number of problems when using them. To load more firewood and not worry about the risk of the coolant boiling, you can install a buffer tank (heat accumulator).

The buffer is a sealed reservoir that separates the unit from the users. Due to its large volume, the container can collect excess thermal energy and move it directly to the radiators. To regulate the temperature, a mixing unit operating on the basis of a three-way valve is used.

Boiler connection

Boiler piping with polypropylene with an indirect heating boiler is suitable for different types heating systems. To implement such a scheme, a Maybes boiler (or any other) is connected to heating and hot water systems, and a coil is placed in the water heater to effectively supply coolant to the main line.

After passing through the heating circuit, the hot coolant transfers thermal potential to the water. In some cases, the tank is equipped with heating elements that allow access to hot water during the warm season.

When installing a solid fuel boiler with your own hands, you must adhere to the following instructions:

- Prepare the installation site for the boiler.

- Organize the wiring by marking the sources of hot and cold liquids with appropriate colors.

- Fix the tee and relief valve, carefully covering all gaps with sealant.

- Turn on the water taps.

- Connect the equipment to the power supply and secure the thermostat with automation.

- Select heating mode.

- Check the system for functionality.

Subject to general advice installation work will be unmistakable.

Collector circuit

If the boiler is equipped with several parallel branches with radiator equipment, a heated floor system and other devices, it will be necessary to balance the circuits. Otherwise, the fluid will move along the path of least resistance. To implement it, it is necessary to use special distribution devices with 1 input and several outputs - collectors.

The use of these parts expands the possibilities for connecting circulation equipment and allows the supply of a thermal agent at the same temperature. The disadvantage of such a harness is considered to be more complex design and high cost of equipment.

Sometimes the boiler is tied with a hydraulic arrow, which becomes an intermediary between the heating boiler and the owners of the premises. The hydraulic structure is placed vertically and connected to the inlet and discharge pipes. In this case, the insertion is performed at any height.

Connection diagram of a heat accumulator to a solid fuel boiler

Among the large number of connection diagrams, the option of installing a heat accumulator for a TT boiler is in great demand.

Using this method, you can reduce heating costs and reduce voltage during peak loads. In order for the system to work for a long time and with high quality, it is important to choose the right equipment, guided by personal requirements and regulations.

It is also necessary to draw up a harness project, which will indicate the basic locations of the working units.

How to reduce the cost of harness

To reduce the cost of piping, you can use a three-way valve with a simplified design, which does not require connecting an overhead temperature sensor and a thermal head. It contains a thermostatic element, which is set to an operating mode with a fixed value of +55...+60°C.

The use of such a part makes it possible to reduce the cost of piping a TT boiler, but deprives consumers of the ability to adjust the temperature using a thermal head.

You can also connect 2 units that operate on different fuels:

- Wood or natural gas.

- Due to electricity.

Connecting a buffer tank with copper or polypropylene pipes (experts recommend choosing options with copper) allows you to simultaneously service different systems in the house: radiators, heated floors, boilers. However, this option requires large investments and is rarely used.

Heating equipment is designed to make life easier and make living in the house comfortable. Why carry firewood and buy coal? It is much more convenient to connect a gas boiler to a common line. It can be mounted both on the wall and on the floor. But how to properly organize heating so that the coolant is distributed evenly throughout the system? How can you save on fuel consumption? Gas boiler piping diagrams will help you.

What does the harness include?

How does the system usually work? It is based on a heating boiler, from which the coolant is distributed through pipes and radiators. Trimming is an installation scheme that protects against overheating and guarantees efficient operation. It includes elements that are located between the radiators and the boiler:

- Pipes, divided into two circuits: supply and return lines.

- Shut-off valves, fittings.

- Expansion tank. Its volume is equal to 10% of the total amount of coolant in the system. When heated, water expands and pressure increases. To ensure that the value does not exceed the critical level, excess liquid is taken into a membrane tank. After cooling, the water returns to the circuit again.

- Safety valve. Has the same function as the expansion tank. Discharges excess water into the sewer, preventing an explosion when pressure increases.

- Air vent. Air pockets interfere with coolant circulation. The air vent automatically bleeds air from the system.

- Pressure gauge- a device for measuring and monitoring pressure.

- Circulation pump. Responsible for the forced movement of liquid through pipes. The pressure and productivity depend on its power.

- Hydroarrow- these are pipes that are combined into a common container. With a hydraulic arrow, you can connect several circuits at the same time, avoiding their influence on each other.

- Coarse filter. Fine mesh detail. Detains debris that comes with tap water (sand, rust).

Automation is installed to control the operation of gas and electric boilers. This is a set of sensors for ionization, draft, ignition, temperature. Each of them controls the operation of a separate node.

The more complex the piping scheme, the more the efficiency of a boiler for a private house or apartment increases.

Strapping schemes

To understand how to make the connection correctly, pay attention to the type of boiler. The connection of a single-circuit and double-circuit unit will be different. The simplest piping does not include a pump. The design uses only shut-off valves and a filter. This is a financially economical approach, but it does not ensure uniform distribution of the coolant.

It’s easier to make the connection with polypropylene with your own hands. Pipes made from this material are inexpensive and easy to install. In addition, plaque and scale do not accumulate on their walls. You can assemble a circuit of any shape; the connections are made using an “American” fit. Paronite is used as gaskets.

Single-pipe (simple) circuit

The instructions are suitable for single-circuit boilers “”, “”, “” and other brands. The design provides for one pipe, which extends from the body along the floor level. The batteries are connected in series, which reduces the heating efficiency (especially since the combination does not turn on the pump).

Advantages of installation with natural circulation:

- Easy installation.

- Independence of heating from the availability of electricity (the pump requires a connection to the network to operate).

- Minimum costs for materials and equipment.

The picture below shows the connection already with a pump and forced circulation.

Two-pipe installation

How to tie a double-circuit boiler? It includes a supply line that goes up (riser) and turns at the ceiling. This is the main pipe, from which a fork diverges separately to each radiator. The outlet pipe is located at the floor line. Each battery is connected to it by a pipe. It is this organization that allows the coolant to be evenly distributed, which means that the room can be heated effectively.

IN one-story houses You can install a heating system with natural circulation. But in multi-storey buildings only the option with a pump is used. What you will need during installation:

- pump (usually included with the boiler);

- distribution valve;

- membrane tank;

- shut-off valves;

- filters;

- check valve;

- adapters, tee.

The piping of a single-circuit gas heating boiler depends on the number of connected devices. The simplest scheme includes the boiler itself and the radiator system. If desired, you can add an indirect heating boiler, a “warm floor” system, heated towels, etc.

The piping of a single-circuit unit may include:

- a gas boiler;

- radiator system;

- safety valve;

- expansion tank;

- air vent;

- circulation pump;

- indirect heating boiler;

- hydraulic arrow;

- coarse filters.

Safety valve necessary to relieve excess coolant in the event of an increase in pressure in the circuit. Otherwise, it may lead to pipe rupture. Excess water is discharged through the drainage pipe into the sewer system.

Most gas units have their own expansion tank– it is necessary to compensate for the increased volume of water or antifreeze in the heating circuit. The volume of the membrane tank should not be less than 10% of the amount of coolant. If the heating system is too large and the built-in expansion tank is not enough, then purchase another one and include it in the piping.

Air vent serves to prevent the appearance of air pockets in the circuit that may remain after draining the coolant.

Indirect heating boiler it is installed so that a single-circuit gas boiler plays the role of a double-circuit one and can produce hot water in addition to heating.

Circulation pump they are included in the piping if the existing analogue in the gas boiler does not provide sufficient coolant pressure in the system. The power consumption of the pumps ranges from 50 to 200 W - it can be changed if necessary.

Hydroarrow is a tube with pipes for connecting several circuits. This piping element allows you to connect circuits with different pressures and coolant temperatures into one system.

Coarse filter placed on the water supply pipe to the gas boiler. It protects the heat exchanger of the unit from debris and dirt from the heating system, which can damage it.

As for the location of all decoupling elements, the safety valve and air vent are usually combined into one safety group. It is placed at the coolant outlet from the boiler, where the pressure and temperature are maximum. The pump is installed in front of the unit in a place where the coolant temperature is minimal. The expansion tank can be installed at any point in the circuit at some distance from the pump.

What pipes are suitable for piping?

To connect the boiler and heating wiring, it is better to take metal-plastic or polypropylene pipes. They will cost less than galvanized or copper counterparts.

Consistent wiring of radiators is carried out using metal-plastic pipes on press fittings or polypropylene pipes with aluminum reinforcement. However, each of these options has its own drawback. Press fittings are sensitive to the quality of installation and leakage may occur at the slightest displacement. Polypropylene has a high elongation coefficient when heated to more than 50°C. For wiring the “warm floor” system, metal-plastic with press fittings, polyethylene or thermally modified polyethylene are used.

Note! It is advisable to install ball valves at the inlet and outlet. This will allow you to remove the heat exchanger or gas boiler without draining the coolant.Piping diagrams for a single-circuit gas boiler

The wiring diagrams for a single-circuit gas heating boiler are as follows:

- piping a single-circuit unit with natural coolant circulation;

- piping of a single-circuit heating boiler with forced circulation;

- connecting a gas heating device with an indirect heating boiler.

Any single-circuit boiler has three pipes to which they connect:

- supply of heated coolant from the unit to the radiators;

- gas main;

- return of cooled liquid from radiators to the gas boiler.

The piping diagrams for a wall-mounted single-circuit gas boiler are identical to those for the same floor-standing unit.

Piping a single-circuit boiler with natural coolant circulation

The system of a single-circuit gas boiler with natural circulation of coolant is completely energy independent. The security group is represented only expansion tank. It is recommended to install a vent in front of the heat exchanger to be able to completely drain the water. Any plastic or metal container with sufficient tightness can be used as a membrane tank.

To ensure the natural movement of coolant through a non-volatile system, an expansion tank should be installed at the top point of the circuit, and a gas boiler at the bottom. The bottling is installed with a constant slope so that the coolant can rise to the expansion tank and then go down to the heating unit. The height difference between the radiator elements and the heat exchanger creates hydraulic pressure.

Note! To ensure the required coolant pressure in a gravity heating system, the internal diameter of the pipes must be at least 32 mm.If desired, a pump can be included in the piping of a non-volatile system, which will accelerate the coolant when electricity is available. It is connected parallel to the main system and is cut off with a ball valve or check valve. When the pump is turned off, the valve or tap is closed, after which the coolant continues to circulate naturally.

Piping of a gas unit with forced circulation

The most popular is the piping of a single-circuit gas boiler with forced circulation of coolant. It is the simplest and most convenient to use. This scheme includes a circulation pump, which ensures the movement of coolant through the system under pressure. However, the pump can only operate on electricity, otherwise the system will not be able to function.

Piping a single-circuit boiler with a boiler

In order for a single-circuit gas boiler to produce domestic hot water, it must be connected to an indirect heating boiler. It contains its own heat exchanger, which acts as a secondary circuit. The coolant that comes from the gas boiler circulates through it.

The boiler is connected to the supply and return pipes of the gas boiler parallel to the heating system. Water pipes are also connected to the storage tank, through one of them cold water enters the boiler, and through the second hot water comes out.

Why is it so important to piping the boiler according to all the rules?

Many owners who decide to piping a gas boiler with their own hands underestimate the importance of the rules for its implementation. But a properly made harness can:

- prevent airing;

- get rid of sand, salts and rust;

- do not allow the maximum permissible pressure in the system to be exceeded;

- compensate for excess thermal expansion;

- make it possible to connect several circuits.

Correctly executed piping ensures reliability, good performance and safety of the entire system.

Recommendations for piping a single-circuit gas boiler

To avoid mistakes when piping a single-circuit gas boiler, you should follow certain recommendations:

- When piping a new gas boiler and an old system, you should thoroughly flush the pipes and radiators so that accumulated deposits do not reduce the heating efficiency.

- Filters are usually placed on a horizontal section of pipe in front of the unit. You need to place them so that the drawn arrow coincides with the direction of movement of the coolant. The sump should be located at the bottom so that dirt does not clog the filter itself.

- Connections between pipes and branch pipes should be made using American couplings.

- Shut-off valves and a check valve must be installed in front of the supply pipe entering the boiler, and a circulation pump must be mounted on the return line.

- The main gas supply should be made rigid or flexible metal pipe. To seal the connection, use only a paronite gasket.

Connecting several boilers to one system

In regions where there is an unstable supply of gas or electricity, they resort to installing two boilers, for example, solid fuel and gas. Two units can operate according to different schemes:

- Serial connection - a thermal accumulator is installed between the units, into which heated coolant is supplied from the solid fuel boiler. Then it is sent to the system with a gas device, and then distributed to consumers.

- Parallel connection - in this case, the operation of the solid fuel unit is controlled by safety sensors. A three-way valve is also installed, with which you can turn off any of the units.

Multi-circuit heating systems are equipped with hydraulic distributors that compensate for pressure differences and balance coolant flows. Sometimes it is possible to organize a system without hydraulics, then the pressure is regulated by balancing valves.

Are there mites in Pitsunda? Ticks in Abkhazia. Pitsunda pine grove

Are there mites in Pitsunda? Ticks in Abkhazia. Pitsunda pine grove Red viburnum (Viburnum opulus L

Red viburnum (Viburnum opulus L Nail Making Business How to Make Copper Nails

Nail Making Business How to Make Copper Nails Stone brazier: material features and manufacturing options

Stone brazier: material features and manufacturing options Blackroot medicinal cultivation

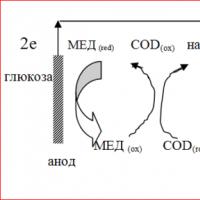

Blackroot medicinal cultivation Fuel cells: a glimpse into the future

Fuel cells: a glimpse into the future Houses with a hipped roof projects

Houses with a hipped roof projects