Stove from a cast iron bath. There are no unnecessary things in the household: you can make an excellent stove from an old cast-iron bathtub. How to make a stove with your own hands

Old stove cast iron bath with your own hands opens up endless possibilities for every craftsman who loves to make things with his own hands.

Collapse

Due to the natural obsolescence of cast iron bathtubs, their cost decreases from year to year, and the benefits during the construction of a furnace cannot be measured by any money.

Forget that your own oven is expensive. All you need is a small set of tools and some personal time.

Construction device

Most often, a cast iron bathtub of the classic type is used, which is divided into two equal parts. The free plane on top is covered with a steel sheet to create a closed space.

The base can be a concrete floor or brickwork. If the cut is made correctly, there will be no open cracks that will interfere with traction.

The actual chimney pipe is connected at the outlet of the drain, which eliminates the need for a number of additional cuts and drilling. It is worth understanding that a stove from a bathtub cut in half can be additionally sold or gifted to close friends, since it is possible to create two stoves from one bathtub.

An example of a stove made from a cast iron bath in the photo:

Conclusion

There is nothing difficult about creating your own stove from a cast iron bathtub. Follow the instructions carefully to get fantastic results. Rest assured that the quality of the stove will not be inferior to industrial models, but the cost will be orders of magnitude lower than that of the original!

←Previous article Next article →If you have an old cast-iron bathtub lying around somewhere in your garage or dacha, you shouldn’t rush to sell it for scrap. It can be used to make an excellent outdoor oven and install on garden plot .

A stove made from an old unnecessary thing will become decoration and an excellent assistant, delighting guests and household members with delicious and original dishes.

Most often, a garden barbecue stove is made from old cast iron bathtubs. The cast iron from which the bath is made, having high thermal conductivity, retains heat for a long time and allows you to cook not only the usual food, but even bake bread and other unique dishes.

How to make a stove from an old cast iron bathtub?

The essence of the construction is that the bath cut in half. The resulting halves are placed one on top of the other, with the curved side outward, and laid metal sheet between them.

It separates the firebox and the chamber in which the food will be cooked. Holes are made in the sheet of iron and the upper half of the bath for chimney and the pipe is welded.

All that remains is to strengthen the structure, give it an interesting look, insert grate bars and do doors.

Necessary materials and equipment

To build a garden stove you will need:

- herself bath, it can be steel, but better - cast iron;

- Bulgarian;

- edged metal cutting circles;

- circles for grinding;

- Metal sheet thick 5 mm and more;

- drill;

- bolts;

- heat-resistant sealant;

- tape measure or roulette;

- pencil or marker;

- welding machine;

- pipe for chimney;

- grate bars;

- bricks;

- clay;

- sand.

Preparatory work

Before you start building a structure, you need to make all the preparations:

- Mark the middle of the bathtub and cut it in half - this work is labor-intensive and dusty, so it's better to spend it outside by turning the bathtub upside down.

- Cut a blank from a metal sheet to the size of the resulting half.

- On a cut sheet of iron and half of the bathtub that will be on top, mark the holes for the chimney and cut them out.

- Weld the pipe into the partition and bring it out through the upper part.

- Do markings for fastenings.

Important! All work on cutting, grinding edges and trimming iron sheets must be carried out wearing safety glasses. And welding work is in special mask.

DIY stove construction

When all preliminary the work is done, you can proceed directly to the construction of the furnace itself.

Foundation

Furnace design quite heavy, so you can’t do without a foundation. It will not allow the device to shrink and deform.

For a structure that is not heavy in weight, the foundation can be brick. For more significant is done bulk— depth up to 50 cm. To ensure that the stove is at a convenient level, supports of the required height are concreted into the foundation.

Further work is being carried out after complete drying foundation.

Assembly of the structure: photo

- Half of the bath, which is reserved for the lower combustion part of the stove, coated with sealant, the top is covered with pre-cut sheet of iron with a welded chimney. You can insert cast iron into this sheet hob.

Photo 1. A cast-iron bathtub, carefully sawn in half, is prepared for applying sealant.

- Top design covered with the other half bathtubs, bottom up, passing the chimney pipe into a pre-cut hole. The edges in contact with the metal sheet are also coated with sealant.

- Both halves of the bath and the sheet between them fastened together with bolts.

Photo 2. The connected halves of the bath form the body of the stove: the combustion chamber and the cooking compartment.

- Finished design mounted on supports in the foundation and lined with bricks. The masonry can be only on the back and sides or on all sides.

- In the lower part - the combustion chamber - is installed grate.

Photo 3. The stove, assembled from two halves of the bath, is almost ready. All that remains is to fit the doors.

If the furnace design provides closed brickwork firebox and vent, then when working immediately doors are mounted: for the blower in the lower part, for the firebox - a little higher, opposite the grate.

Important! The damper or door handle must be wooden to avoid burns.

The wall is laid out to the junction of the edges of the bathtub with each other. The bricks must fit tightly to all edges of the stove.

For the top compartment stoves are provided flap or door. In the tightly closed part you can not only cook any dishes, but even bake bread.

Insulation of the cooking chamber

Upper half drags on mesh, throws a solution of 1 part clay and 2 parts sand, thickness up to 7 cm and levels out. You can decorate the top wild stone, pieces heat resistant tiles or simply whitewash.

The final stage

That's it - bake ready, you can already use it. But many are trying to give it more modern look Why is rough work hidden? beautiful brickwork, veneer wild stone or decorative tiles.

Photo 4. Finished whitewashed cast iron stove from a bathtub, installed in the garden on a brick base.

Possible difficulties during work

Problems when constructing a garden stove, problems may arise on preparatory stage when cutting into an old cast iron bathtub.

Advice. Work is carried out wearing glasses and thick clothes, covering the body.

It needs to be cut carefully, slowly. First, the enamel layer is cut along the marking line to prevent chipping. Then the cast iron is cut at an angle, making small slits, and not allowing the angle grinder to overheat. To prevent the disc from being pinched by the bath halves, the incision site is expanded wooden stick or brick.

When it's time to replace your bathtub, don't rush to throw it away. A stove made from a cast iron bathtub will be a worthy continuation of the life of the old Soviet plumbing element.

Advantages

The material from which the bathtub is poured deserves special attention. Cast iron has always differed from steel in its ability to retain heat during water procedures. Over the years, this property has not changed. Due to its good thermal conductivity, an old cast-iron bathtub is often used in the construction of a stove.

Cast iron is ideal for creating a stove

Cast iron products do not have an expiration date. They are not subject to corrosion and have high strength. It accumulates and releases heat well. Today, industrial enterprises produce fireboxes and grates from cast iron, because they do not burn out. We will simply use old material for new purposes. The only drawback of cast iron is its fragility. It is important to remember this when performing any work with this heavy material.

Video “Stove from a cast iron bath”

From this video you will learn how to make a stove from a cast iron bathtub with your own hands.

What can it be used for?

This material is used in the construction of stoves for various purposes:

- For a bath or sauna. When turned upside down, it will serve as a firebox (stove).

- For the garden, two transversely cut halves are used: the lower one as a firebox, the upper one as a place for cooking food.

- For a small room, one made in the form of folded two halves will be a good fireplace.

- Barbecue using one half of the bathtub, bottom down.

Preparatory stage

To make a stove from an old bathtub, you will need the following materials:

- the bath itself;

- Red brick;

- cement, sand, clay;

- crushed stone;

- steel sheet with a thickness of at least 4 mm;

- lattice or perforation;

- finished door with frame and hinges for the firebox;

- steel pipe for chimney;

- boards for formwork;

- roofing felt or polyethylene for waterproofing.

The cast iron bath for the stove needs to be sawed in half

The cast iron bath for the stove needs to be sawed in half Necessary tools to complete the work:

- shovel, trowel, spatula;

- metalworking tools;

- electric drill with drills;

- grinder with high-quality cutting discs;

- measuring and marking tools;

- mounting gun for working with sealant;

- welding machine.

In preparation for work, it will be necessary to transport the old bathtub to the place where the stove is manufactured. Considering its large weight and the need to cut it in half, it would be more correct to make the cut before transportation.

Correct cut

The material of the font, which is to be sawed in half, is very fragile. Therefore, we must take this stage of work very responsibly:

- Turn the bathtub upside down and secure it in a stable position.

- Mark the cutting line taking into account the width of the cutting tool.

- Slowly, strictly according to the markings, make an incision along the entire line. This will destroy the protective layer of enamel, and when cutting, it will protect the cut end of the cast-iron font from chipping.

- Carefully, slowly, taking pauses for the tool and the cast iron being processed to cool, we will cut the bath in half. When carrying out such work, it is important to remember safety measures: use safety glasses and a respirator or gauze bandage.

It is advisable to install such a heavy building on monolithic foundation

It is advisable to install such a heavy building on monolithic foundation Technological process

Now that the source material is ready, we determine design features the furnace being built, the installation location, and we begin construction.

Creating a foundation and installing sheets

To build a furnace, the foundation can be made as a strip foundation by digging a trench around the perimeter of the future structure. But given the large weight of the font and the bricks with which the outer part will be laid, it would be better to make a monolithic foundation.

Step-by-step instruction:

- Let's mark the selected location. The marking boundaries should be 10–15 cm larger than the area of the future structure.

- We will dig a pit to a depth of 30–40 cm.

- We will construct a sand and gravel base. To do this, cover the bottom evenly with crushed stone, then with sand. Let's moisten and compact all this.

- We will build formwork around the perimeter of the pit. The height of the future foundation is no more than 30 cm from the ground.

- Using scrap metal, we reinforce the internal cavity of the pit. We tie with wire hardware inside the pit.

- Fill the inner cavity of the pit with concrete. Using the level rule, we make the top layer horizontal.

- Let the foundation dry completely.

After pouring concrete into the foundation, you need to let it dry for several days.

After pouring concrete into the foundation, you need to let it dry for several days. While the frame hardens, we will select the required sheet profile for the partition. Its thickness must be at least 4 mm. The main requirement for a sheet is its straightness. If it has any defects, it will be impossible to install the upper part of the stove evenly.

Apply the sheet to the outline of the upper part of the sawn bathtub and draw it. Let's cut out the future partition. Mark and cut a hole for the chimney pipe. It is placed opposite the drain hole of the second half of the font.

After the foundation hardens, we will prepare the installation site. To do this, we will lay out several brick stops that will support the side walls of the bathtub. Let's install the font on the foundation. For the bottom of the oven, you must use the half that does not have a drain hole. If the bathtub is not very stable, then we will put temporary supports around the perimeter. Let's make them from timber.

Before installing the sheet, it is necessary to degrease the surfaces that will be in contact. After this, you need to apply sealant to the upper surface of the bathtub. The sealant used must be heat resistant. The use of other adhesives will compromise the tightness of the joint. It is this surface that will be exposed to high temperatures.

Chimney pipe

We have already cut a hole in the steel sheet for the chimney. Now let's do the same in the bathroom. Considering the high strength and fragility of cast iron, this work is no less important than cutting:

- Around the drain hole we will mark the diameter of the future chimney. On a steel sheet, this size corresponded to the diameter of the pipe. In the upper half of the stove, a hole for the chimney is cut out 1–2 cm larger than the outer diameter of the pipe.

- We carefully drill holes along the intended circle line, pausing to allow the cutting surfaces to cool. Drilling should be done as tightly as possible.

- Slowly, using a good quality small diameter cutting disc, connect the holes with slits.

- Use a file to clean out the unevenness of the cut line.

It is important to cut the hole for the chimney as carefully as possible

It is important to cut the hole for the chimney as carefully as possible Now let's weld the pipe to the sheet. The length of the pipe must exceed the structure of the stove assembly by at least 1 m. When carrying out welding work, we control the verticality of the future chimney. It is important to remember safety measures: use a working machine, protective clothing and special glasses or a welder’s shield.

Before installing the second half of the font, degrease the joint surfaces and apply heat-resistant sealant. Lift the top half upside down over the chimney and place it in this position on a steel sheet. Align the edges of the lower and upper parts, remove excess sealant with a rag. Allow the assembled structure to dry.

To create greater structural rigidity, we fasten the two halves of the bathtub in adjacent surfaces with bolted connections. Drill holes for bolts carefully, remembering the fragility of the material. Seal the gap between the chimney pipe and the hole in the upper half of the stove with sealant. If there is a large gap, make a metal sealing ring.

Lattice

Now we install the grates on the bottom of the future furnace. They are made of cast iron or high carbon steel. The surest solution would be to install a cast iron grate, which in width will be slightly larger than Bottom part baths. If necessary, adjust the size of the grate so that the grates are installed at a height of 10–15 cm.

The most the best solution for the bottom of the oven there will be a cast iron grate

The most the best solution for the bottom of the oven there will be a cast iron grate In the case when the grate size is smaller than desired, it is necessary to weld a couple of corners at the desired height and install grate bars on them. It is better to carry out welding work in the lower part of the furnace before assembling the entire structure. Therefore, ensure that the grate is the correct size for the grate before installing the sheet on the bottom half of the font.

Masonry

In this form, the oven can already fulfill its functional purpose. But a large amount of heat is transferred through the external walls and is not used. In addition, the appearance of such a design does not give positive emotions.

Let's start finishing work. Let's start with brick laying. The brick must be solid, solid red. We lay out the bottom row the width of a brick. Using the terminology of masons - a poke. Then, laying bricks around the perimeter, we will make half-brick masonry. Each subsequent row should be staggered. The solution used is supplemented with lime to eliminate the possibility of cracks.

If necessary, we will strengthen the rigidity of the furnace structure with internal brickwork and remove temporary supports. When laying the lower front part of the stove, we will fix the prepared door with the frame into the masonry itself.

For greater functionality, the stove must be lined with bricks

For greater functionality, the stove must be lined with bricks Usually there are two such doors: the upper one for storing firewood, and the lower one for adjusting the draft. We will finish the laying at the height of the first half of the bathtub.

Decor

To retain heat in the roasting pan and improve appearance We will finish the upper part of the structure with several layers of sand-clay mixture. This mixture must be prepared in advance. It is best to soak the clay in a bucket two weeks before use. Periodically add water and stir. Before use, add sand and a small amount of lime.

We will cover the upper part of the stove with a metal mesh, firmly fixing it at the edges. Let's apply the first one thick layer mixture, and after drying - finishing. The resulting thickness should be 6–8 cm. Roughness and unevenness will be rubbed off. Let's whitewash the top part of the structure.

To increase the cooking capabilities of the new unit, we will cut a damper out of metal. Its size should match the end of the fryer. The thickness of the damper is made small - 0.5–1 mm. We weld the handle to the damper and paint it, along with the doors of the lower half of the stove, with black fireproof paint in several layers. This will give contrast.

Our oven is ready for use. Let's start cooking food in the fresh air and evaluate the possibilities of its use.

Over time, even a high-quality bathtub becomes unusable, so old cast-iron vessels, as a rule, are sent to a landfill. Just don’t rush to do such an act, because you can use this product in a new way, give it new life. For example, from an old bathtub you can make a pond in the country, a bench and even a stove. If you saw an old vessel crosswise, you will have an excellent DIY bathtub stove. It can be installed in a bathhouse or in a garden plot, the main thing is to be able to handle welding machine, because this process cannot be done without it. This material will help you with this; you will produce a high-quality, durable and useful structure.

What will you need for the job?

To make a stove from a bathtub with your own hands, purchase and prepare all the materials, fixtures, and tools necessary for the work.

Important! You need to understand that sawing a cast iron structure, in particular a Soviet-made one, is quite difficult, because previously manufacturers did not spare the metal.

To work you will need the following tools:

- Small Sander or Bulgarian. It is important that it be reliable, because a low-quality tool will not cope with such a task.

- Circles for cutting metal with a diameter of 125 mm and a thickness of 1 mm. You will need 3-4 circles, it all depends on the thickness of the cast iron.

- Grinding wheels. They are necessary for processing cut sides of metal.

- An electric drill with metal drills for drilling holes in a product.

- Welding machine.

- Spatula and trowel for finishing work and brickwork.

- Construction pistol.

- Building level.

- Plumb.

- Hammer.

Materials you will need:

- Cast iron bath.

- Metal sheets 5 mm thick.

- Two-burner cast iron hob.

- Brick.

- Grate.

- Sand and clay for making masonry mortar.

- Heat-resistant ready-made adhesive mixture.

- Sealant.

- Bolts with washers and nuts.

- Metal mesh for reinforcing clay mortar.

- Ceramic tile.

- Metal corner.

- Chimney pipe with a diameter of 110-120 mm.

- Safety glasses, respirator, construction gloves.

How to cut a cast iron bathtub?

As we have already said, making a stove from an old bathtub with your own hands is not so easy, and the most important and difficult process is cutting it. The most important stage is, of course, a high-quality cut of a massive structure.

- If you decide to cut indoors, then first do the preparatory work, since cast iron dust will fly in all directions and can ruin everything that is around. Therefore, empty the room of all objects.

- Mark the future cut, because you need to divide the bath clearly in half.

- Considering that the structure is covered with a thick layer of enamel, first of all, cut it according to the line of the future cut - this will avoid the formation of chips along the edges.

- Carefully saw through the cast iron using small 100-120mm cuts.

Important! Do this at an angle so that the disc does not peel off the enamel when moving back. Make sure that the grinder does not overheat.

- After the cutting is completed, place supports under each half, for example, from stacks of bricks. This is done so that at the final stage they do not close along the sawn line and do not pinch or tear the disk.

Having all the necessary tools at hand, you can complete the job in an hour.

Important! Since the bathtub must be cut exactly in half to make the intended structure, make sure that the symmetry is not broken.

How to make a cast iron stove with your own hands from an old bathtub?

After execution preparatory work deliver the cut bathtub to the installation site, and you can begin building the planned structure.

Perform production using this technology:

- In the place where the stove made from a cast-iron bathtub will be installed with your own hands, build a foundation.

Important! This must be done, since the product will turn out heavy and it will begin to shrink without a reliable base. As a result, the entire structure may become deformed.

- Place the lower part of the bath on a dried foundation. If you want it to be higher, then raise it with supports and secure it to the concrete mortar. While the base is strengthening and drying, start making other parts.

- You can make the oven in two variations, and here everyone decides for themselves what to choose. In the first case, its façade is made entirely of metal walls, in the second, the vent and firebox are covered with a brick wall into which metal or cast iron doors are built.

- Attach brackets for mounting the grate on the walls of the lower half-cylinder. It is needed to separate the ash pan and the firebox, so it is better to raise it slightly above the bottom of the bath by 15 cm. Attach the metal corners to the marked walls of the product and place the grate on them.

- Cut a sheet of metal to cover the bottom of the firebox. Then, in cast iron, cut a hole for the chimney pipe along the intended contour of the circle, first small holes, then carefully combine them with a grinder, and file the resulting opening to the required configuration.

- Coat the combustion part with fire-resistant sealant and cover it with a metal sheet with a chimney pipe built into it. Place the second part of the bath with a hole for the pipe on top of the sheet. Also treat it with sealant before installation. As a result, you will put the upper part on the pipe and increase the chimney to the desired height.

- Tighten both parts of the bathtub and the metal sheet located between them using bolts with a diameter of 10 mm. First, drill through holes in the sides of the bathtub in increments of 15-20 cm, then fasten all the elements through them into a single structure.

- Separate the blower and combustion chambers with a grate. Place the grate on the prepared corners on the walls.

- Proceed to masonry work. The walls will be located on three sides of the future structure, that is, at the back and sides, or along the entire perimeter of the chambers. First of all, the masonry lines along the foundation are marked, and only then the walls are built.

- If you decide to close the firebox and vent on the front side brick wall, then install the blower door in the wall no lower than the level of the bottom of the bathtub, and the furnace door slightly higher than the grate. Fold the walls to the level of the cooking chamber, expand them inward so that the brick fits more tightly to outside designs.

Important! In this case, it is better to close the cooking chamber, which can be used as an oven, with a metal damper. To ensure that the damper closes the chamber tightly, attach a metal corner in front of it, and the distance from it to the front cut should be 2 mm greater than the thickness metal door. The handle on the damper must be protected from overheating to avoid burns, so it is better to make its gripping part from wood.

- As soon as the entire lower part is covered with brickwork, proceed to insulating the cooking chamber. To create a fur coat, it is better to use a clay solution that has low thermal conductivity. Prepare the mixture, add a little sand to it, after it dries, add lime to it. Leave it to steep.

- Cover the cooking area with metal mesh and attach it to the brickwork on the sides and back. Apply the solution on top of it in two layers so that the thickness of the insulating coat is 5-7 cm.

- Now it’s time to take care of the aesthetic appearance of the stove, because it should not only perform its main functions, but also decorate your area. You can cover it ceramic tiles in the form of a mosaic, only for this you will have to first break it into small pieces. Install using a special heat-resistant compound.

Important! As a result, you will get an excellent DIY bath stove. In the summer you can cook on it every day, thereby saving gas and electricity. It is worth noting that food prepared in this way turns out to be more tasty and aromatic than food prepared on a conventional stove.

How can you reuse an old cast iron bathtub?

In addition to the above method of transforming an old bathtub, there are many more interesting ideas, allowing you to make something really useful out of it.

Let's take a closer look at the most successful of them:

- The bathtub can be converted into a fireplace insert. The advantage of using cast iron in this way is that there is no need to construct a complex semicircular shape from brick. To make a fireplace with a firebox with an arched vault, you need to prepare a template from plywood or boards, then do a few simple manipulations and cover the structure with brick. All that remains is to make a hole in the ceiling of the old bathtub to remove smoke and decorate it with a fireplace portal on the front side.

- A sawn bathtub can be converted into a firebox for a bath. Even a novice master can understand how to make a stove for a bathhouse from a bathtub. It is enough to install it with the dome up, install one part on a concrete base in the steam room, and the second - build into the wall and take it to another room where the stove will be lit. Next, the cut hole must be covered with a brick wall, and a blower and combustion door must be installed in it.

The transformations of old cast-iron bathtubs amaze with their diversity, originality, and beauty. Therefore, do not immediately get rid of unnecessary plumbing fixtures; perhaps they can serve you for many more years, only in a different form!

Ecology of consumption. Estate: What folk craftsmen can come up with to build with their own hands from improvised means. If you have an old cast-iron bathtub, which is usually used for watering the garden, and the construction of a bathhouse is imminent, then you can save a lot by making a stove into a steam room from this bathtub.

A stove made from a cast iron bath will last almost forever. Even enamel will not burn out quickly. In Soviet times, enamel was applied in two layers. The enamel contained quartz sand. After coating with enamel, the product was baked in an oven at a temperature of more than 800 degrees. The sand melted, and this coating served for decades. The enamel could only be damaged by a strong blow from a heavy object.

In addition, cast iron has a high heat capacity, accumulates and releases heat well. Not afraid of corrosion. The industry produces fireboxes and grates from cast iron, since it does not burn out for a long time, unlike steel. But cast iron is a rather brittle metal.

Cutting the bathtub

It is best to saw the bathtub outdoors, after turning it upside down. Cast iron is a brittle metal, so the procedure requires care. The cutting is done with a grinder. Buy several cutting discs at once. We make markings, and then lightly cut the enamel along the line so that when a full cut is made, chips do not form. We saw through the cast iron at a slight angle and make sure that the tool does not heat up. We take breaks. To prevent the halves of the sawn tub from pinching the disk at the final stage of cutting, place supports made of wood or brick along the edges of the cut.

Bathroom cutting is done with a grinder

Furnace foundation

The type of foundation depends on the total weight of the furnace:

- A brick base is suitable for a light stove. The bricks are laid on edge and bonded with mortar. Cement grade for binder mortar is not less than M300;

- for a heavy furnace weighing more than 700 kg, a self-leveling foundation with a depth of at least 50 cm will be required. Formwork is made and filled with liquid concrete with or without filler. The filler will be fine broken brick or crushed stone.

The top of the base is placed flush with the floor or 15 cm below the floor level. To protect the base from moisture, the bottom and walls of the formwork are covered with roofing felt and all joints are coated with bitumen.

Advice. The base should protrude 50 cm beyond the boundaries of the stove. In front of the combustion chamber, 1.2 m of space should remain free.

Furnace No. 1

This version of the stove is capable of heating a bathhouse of 7 square meters. m to 80 degrees in just a couple of hours. To build a stove you will need scrap metal: a cast iron bath, a gas cylinder and a metal drum from a conveyor belt with a diameter of 40 cm. The drum can be replaced gas cylinder or a pipe - this will be the combustion chamber. The sequence of work is as follows:

Advice. If you weld a flat metal platform to the cylinder, you will get a stove for heating the kettle.

Furnace No. 2

From a cast iron bath sawn into two parts you can make a combustion chamber for a sauna stove. You will need one half, the second can be used for the fireplace.

The remaining half can be used to build a fireplace. Cast iron can easily withstand brickwork if you line the fireplace with an arched vault. Moreover, for this you do not need to make a complex template from plywood. The front part is decorated with a portal. The chimney is removed. You can make the fireplace closed by installing a transparent door on the firebox and admire the flames.

Advice. Cast iron and red ceramic bricks have different coefficients of thermal expansion. Therefore, when constructing brick walls, expansion joints are provided, which are filled with asbestos or fire-resistant basalt cardboard.

Furnace No. 3

The third version of the stove is often used as a garden barbecue and for cooking in the summer. If the upper chamber is filled with stones, then such a design will replace a traditional stove in a small bathhouse, so we will not ignore this model.

- The foundation for the furnace is being poured.

- The bathtub is sawn into two identical components.

- Supports are placed on the foundation if you want the stove to be higher.

- The first half of the bath is installed. A sheet of metal with a thickness of at least 5 mm is laid on top, which will completely cover the upper and lower compartments and serve as a hob.

Construction of a barbecue stove from a cast iron bath

- We cut the chimney pipe into the sheet and weld it along the contour.

- We install the second half on top with the bottom up, having previously cut a hole for the chimney.

- We glue the metal sheet and the halves of the cast iron device with high-temperature sealant. This will prevent smoke from entering the upper chamber.

- We clamp both parts with clamps and drill holes along the contour for 10 mm bolts. We fasten both parts of the bathtub and the metal sheet.

- We lay a brick pedestal under the three-wall oven.

- The grate is installed 15 cm from the bottom of the combustion chamber. If the grate size is small, then two corners are welded to install it.

- The front part is covered with a sheet of metal or brickwork with a door installed opposite the combustion and ash chambers.

Finished product from cast iron bathtub and sheet metal

Finished product from cast iron bathtub and sheet metal

- A metal shutter is made according to the size of the upper chamber. In this form, the chamber can be used as an oven.

- Now all that remains is to give the product a noble appearance: cover the brick with tiles or plaster.

Such non-standard designs are easy to manufacture and require minimal financial costs. An item that has served its purpose will get a second life, and you will receive a convenient and practical stove that will serve you faithfully for many years. published

Universal stove for a bath: video

Are there mites in Pitsunda? Ticks in Abkhazia. Pitsunda pine grove

Are there mites in Pitsunda? Ticks in Abkhazia. Pitsunda pine grove Red viburnum (Viburnum opulus L

Red viburnum (Viburnum opulus L Nail Making Business How to Make Copper Nails

Nail Making Business How to Make Copper Nails Stone brazier: material features and manufacturing options

Stone brazier: material features and manufacturing options Blackroot medicinal cultivation

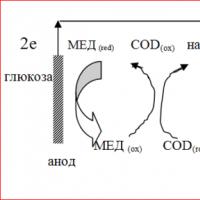

Blackroot medicinal cultivation Fuel cells: a glimpse into the future

Fuel cells: a glimpse into the future Houses with a hipped roof projects

Houses with a hipped roof projects